Our 6 favorite digital techniques

Some of the DE editor’s favorite digital techniques ever.

We recently asked several leaders in the dental lab industry what they thought the biggest issues in their field is right now. One answer kept consistently coming up: digital workflow.

If you haven’t started introducing digital processes into most every part your workflow, it’s probably time to start. And even if you’re already an expert on all things digital, from case creation to fabrication, using design software and 3D printers with ease, chances are there’s still a lot out there to learn.

The lab workflow is changing all the time, and labs are going to have to keep up - or get left behind.

To help with that, the DE editors have selected some of our favorite techniques from over the years highlighting just what can be done with the latest technologies and a little know-how. It’s an exciting time for the lab, and we think you’ll agree with us when we say that newer techniques, materials, equipment and software are making the most beautiful (and most durable) cases ever.

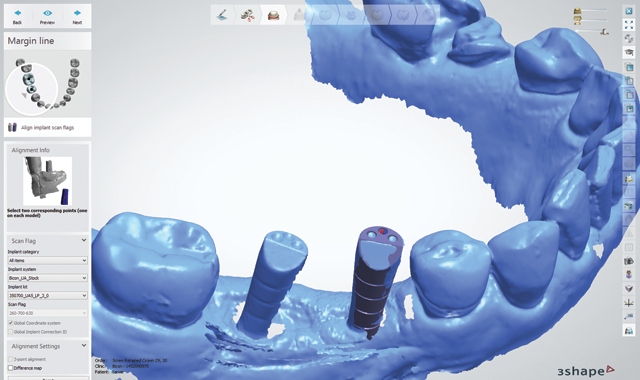

Technique: Scan a complex implant case more efficiently

By Luke S. Kahng, CDT

I have spent the last decade going full force into digital dentistry and mastering the most efficient and successful ways to use state of the art technology to masterfully craft the complex cases that I routinely handle.

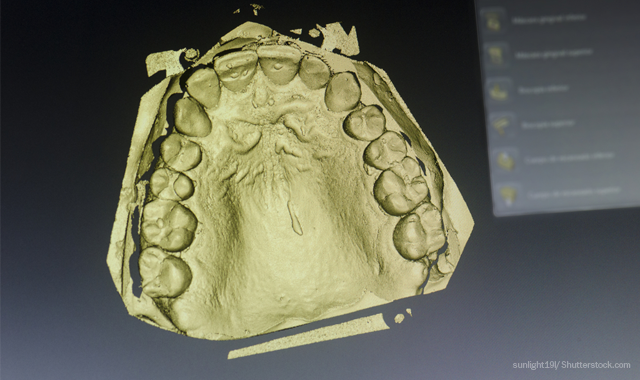

I recently started utilizing the Freedom HD Scanner by DOF for milling in my lab, which allows me to streamline the process of fabricating these cases. The Freedom HD Scanner is fast and compatible with our articulators and allows all-in-one milling, which combines three steps into one. Being able obtain a pre-scan, detailed scan and antagonist scan all in a single step is a remarkable, time-saving convenience for my extremely busy laboratory.

Click here to see how scanning can save you time and money

Technique: Digital case management of a delayed immediate implant placement

By Dr. Robert Pauly, Jr.

A 68-year-old female presented to my office with a toothache on the lower right side. She stated that the tooth had been hurting sporadically for a week and was worsening in duration and frequency. A review of her medical history showed high blood pressure controlled with medication, but otherwise no medical contraindications.

Upon examination, it was revealed that tooth #30 had large MOD alloy that had fractured with large recurrent decay present. Tooth #29 had previous root canal treatment and a fractured crown; all that remained was the root. After diagnosing the site, I informed the patient of the following treatment options.

Click here to see what the patient decided

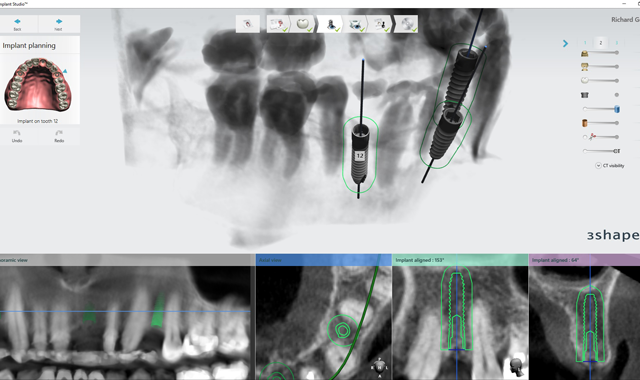

How guided implant surgery can deliver better patient care

By Mark Ferguson

As dentistry has moved to a digital platform, more clinicians and labs have started taking advantage of enhanced communication tools in order to provide greater patient care.

The accuracy currently achievable with digital dentistry is unparalleled. This accuracy, along with teamwork within the surgical and restorative team, is creating workflows where the final outcome can be visualized before a case is started. Implant dentistry is no different.

Click here to see a digitally-planned surgery guide

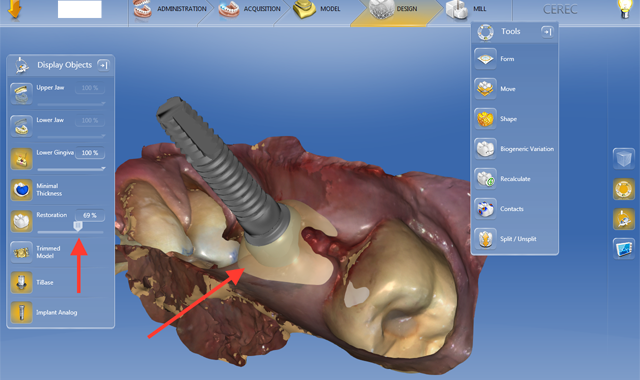

How to do same-day implant restoration

By Daniel Butterman, DDS

Prior to the advent of CAD/CAM dentistry, restoring implants using the analog method required PVS impressions and multiple appointments. In the first appointment, a traditional impression was taken and sent to the lab for fabrication of the implant restoration. Several weeks later, the patient presented for the seating of the restoration.

CAD/CAM dentistry allowed dentists to image the implant digitally and eliminate PVS impressions. It also enabled us to design and fabricate the restoration, as opposed to sending it to a lab, giving the dentist the ultimate control over emergence and tissue pressure. Using this method, the final restoration can be delivered approximately two and a half hours following imaging, or in a subsequent appointment.

Click here to see how a CBCT scan helps create quick results

Technique: Using digital diagnostic design to achieve great results

By Jonathan L. Ferencz, DDS, FACP

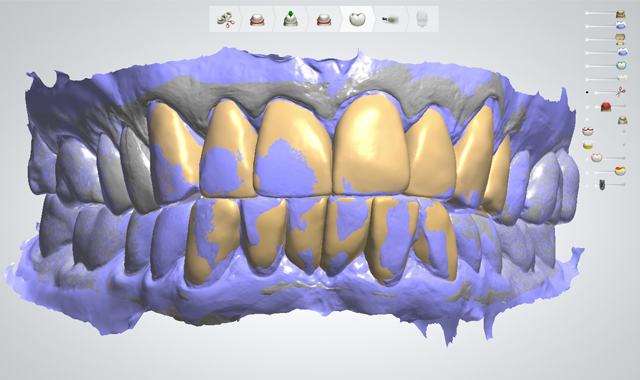

Digital intraoral scanners, as well as stand-alone and complete computer-assisted design (CAD)/computer-aided manufacturing (CAM) equipment are powerful and efficient tools in today’s dental practices. They eliminate the need for traditional analog impressions and wax-ups, as well as the conventional hands-on fabrication processes associated with all-ceramic restorations.

As a result, in one digitally centered workflow that could be implemented, impressions are taken with an intraoral scanner, not conventional materials and trays. Computer software is used to digitize, analyze and manipulate the scanned images, instead of pouring models. Restorations are designed with CAD software, not by hand-waxing models, after which they are milled through a CAM process, rather than by pressing and/or layering.

Click here to see how digital designs save time and effort

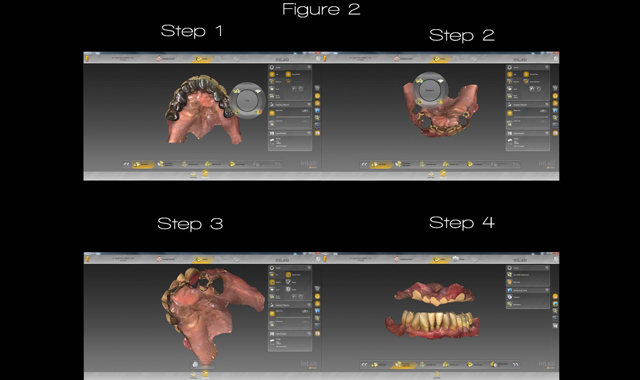

Technique: Creating an immediate load denture using digital tools

By Tra’ Chambers Owner of Express Dental Laboratory, and Dr. Steven Park

The dental industry is currently experiencing a major revolutionary shift in the laboratory design process, slowly but surely transitioning from the traditional physical model to a new age of digital design.

At Express Dental Laboratory, we pride ourselves on being an industry leader by utilizing many innovative new technologies available from Dentsply Sirona in order to manage our workload more efficiently and, in turn, providing our dental partners with a streamlined process of communication and superior deliverables.

Click here to take an in-depth look at a denture case