Why one lab tech said “Primopattern is basically magic ...”

The Lab Precision Dental Arts is a dental laboratory located just outside of Cleveland, Ohio. Specializing in fixed prosthetics, the two-man lab has been in operation since 1997 and mostly works with all-ceramics and implants.

The Lab

Precision Dental Arts is a dental laboratory located just outside of Cleveland, Ohio. Specializing in fixed prosthetics, the two-man lab has been in operation since 1997 and mostly works with all-ceramics and implants.

Last year, about 37 percent of the cases handled at Precision involved implants in some way. Precision also works on many guided surgery cases, and actually co-owns a CBCT scanner with a local prosthodontist. Precision has around 20 core clients it works with every month, along with a number of one-off cases it handles for clinicians in the area.

The Product

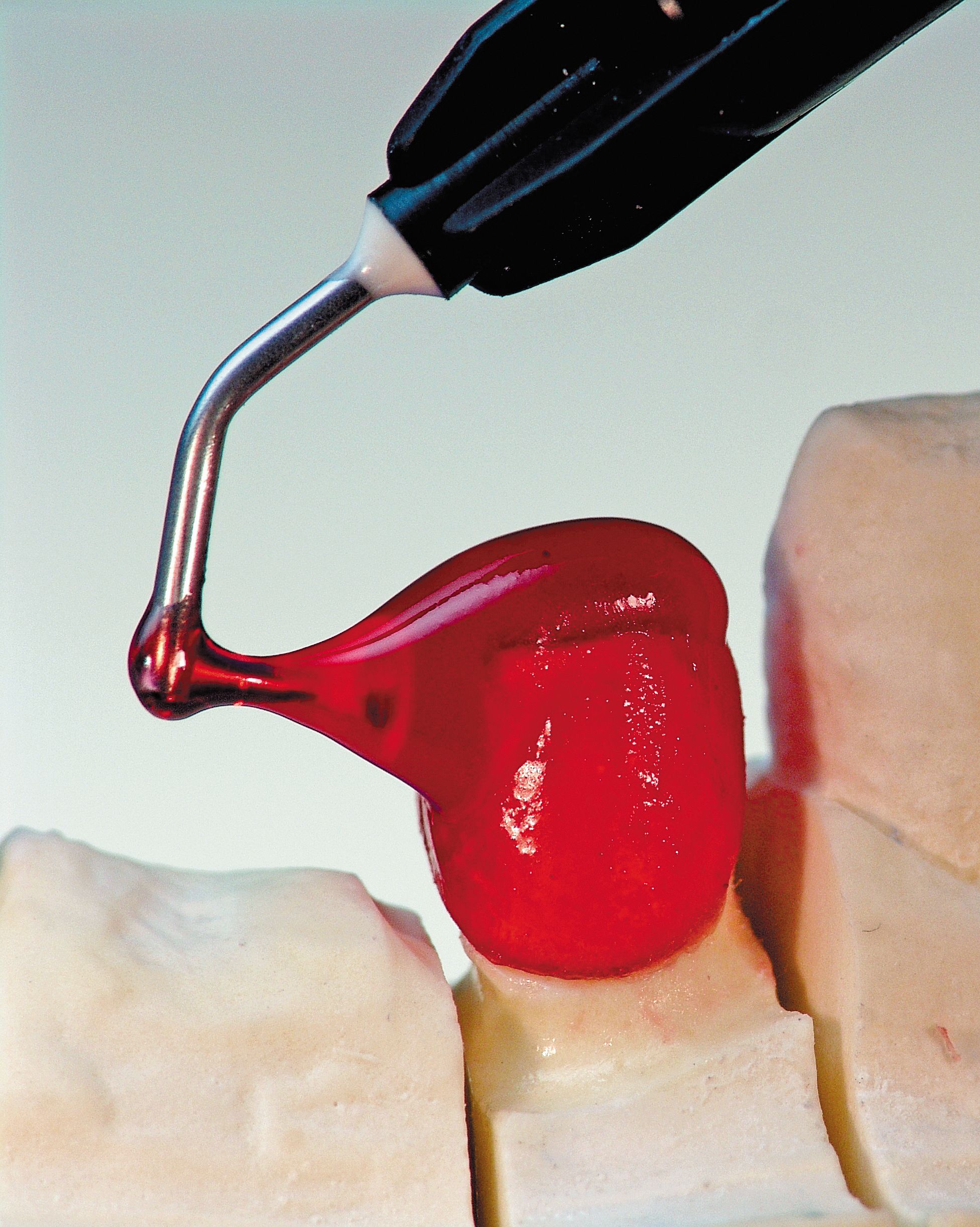

Primopattern LC from primotec is a light-cured universal modeling resin. It comes in both a paste and a gel. The gel does not run, making it an economical solution for a variety of applications. Primopattern is designed to have a long working time (more than 20 minutes) but a very short curing time (less than five minutes). The gel syringe comes with a handling tip that ensures desired precision. The paste is suitable for larger components (bars, pontics and more) while the gel is said to be ideal for delicate work that requires less layer thickness. Primopattern can be used with a grinder, and burns out cleanly. Finally, primopattern demonstrates no distortion or shrinkage issues more common to wax materials.

The Results

Richard Wooddell is the president of Precision Dental Arts, where he serves as the waxer/finisher/framer (his partner, Michael Deliberato, is the lab’s ceramist). He’s been using primopattern LC in the lab, and says it’s revolutionized his ability to easily make accurate models. “Primopattern is basically magic to a waxer,” Wooddell says. “I think it’s one of the top products that I’ve seen in 20 years. [It’s so great to] be able to take something that’s light-cured and build a full-contour unit in half the time, that’s stable enough that you can work on implant bridges, and know it’ll fit. Shrinking is minimal.”

A claim of “magic” is a heady one to use for any one product in a lab’s workflow. But Wooddell lists a number of qualities of primopattern LC that, for him, make the magic label a very apt one. “Say it’s a bridge, whether implant based or natural tooth based,” he explains. “Instead of dipping my copings in wax, I start with primopattern right on a lubricated die. If you were going to wax it conventionally, you’d worry about shrinking, but when you’re working with primopattern, you can begin right with primopattern and then finish the wax up with conventional wax, and you don’t have to worry about shrinking because it’s already been polymerized.”

Primopattern has been available in a red shade for some time, but in mid-2013, a clear version was released. This opens the resin to a wider variety of cases, since it can both be used in the lab for modeling purposes, and for cases when clear would be preferred, such as a guided surgery situation. “We use both red and clear,” Wooddell explains. “When I’m waxing, I use the red, because I can see it. I use the clear primarily for attaching sleeves, because you want the surgeon to be able to see.”

Wooddell’s preference for primopattern over wax is evident. But primopattern LC is hardly the only modeling resin out there-how does it stack up to other resin options? “Shrinkage is less and it burns out absolutely clean,” he observes. “There’s no ash. If you’re looking at casting something, especially if it’s implant-based, then you must have a very clean burn out material. We do a lot of full contour e.max. Those wax-ups are so clean when they come out. From those two factors, I think it’s a superior product to anything to the market.”

Applying Primopattern LC gel.

Primopattern also comes in both a gel and a paste, which are designed to help with smaller and larger cases, respectively. “Primarily, I use the gel but if you have a large pontic, and you want to form that section very quickly, you can take a finger-full of the primopaterrn paste, shape it in the rough form you want, cure it so all the shrinkage has taken place, carve it, and then attach it to the individual copings with the gel,” Wooddell says. The paste makes it easy to save time even on a large case. And according to Wooddell, that saves time.

“From a technician’s standpoint, even though we have preformed pontics with electric waxers, this is still a time-saver,” he observes. “With an electric waxer, it’s drop by drop-it’s not that way with primopattern. If I’ve got a big case to wax, I go straight to the primopattern.”

Wooddell is also happy with the feedback he’s gotten from clients on the work he’s produced using primopattern LC. “Most of us live by ‘no news is good news,’” he laughs, “but when doctors are calling you and saying, ‘I don’t know what you’re doing, but this fits like a glove,’ you know you’ve got something. It’s increased our accuracy, it’s cut down our waxing time, and it’s allowed us to wax frameworks that are very thin but very stable when needed.

“If you were to compare the cost of primopattern versus wax, there’s a big difference in material cost, but when you look at the time savings or units per hour that can be produced, there’s a huge advantage. If the average tech can produce two more cases an hour, do the math! That’s a no-brainer.”