Staining Profiles: Comparing CAD/CAM Blocks and Direct Composite Resin

Research indicates that composites with higher water sorption will have increased staining over time.

With the increased popularity of CAD/CAM products and processes, indirectly placed composite resin materials are used more frequently for a variety of clinical applications to replace missing tooth structure in anterior and posterior teeth. Wine, coffee, and tea commonly cause significant staining in direct composite resin materials because of their low degree of polymerization.1-3 CAD/CAM composite resin blocks show promise in resisting the staining that directly placed composite materials are susceptible to because of prepolymerization of the CAD/CAM composite block; however, there is limited published research comparing the staining susceptibility of new CAD/CAM composite blocks with direct composite resin materials.

CAD/CAM composite resin was initially developed as an alternative to ceramics and direct restorative materials.3,4 CAD/CAM composite blocks are processed under standard conditions of high pressure and temperature, resulting in less polymerization shrinkage than direct composites following polymerization with a curing light.4 Resin composite CAD/CAM blocks offer advantages over glass-ceramic blocks, including enhanced margin adaptation and easier milling.5 CAD/CAM composite resins are also easily repairable, which makes them a suitable choice in many clinical situations.4 Although the fabrication process of CAD/CAM composite blocks differs from that of directly cured composite resin, they share similar composition.3,4 For example, Paradigm MZ100 (3M), a CAD/CAM composite material, contains Bis-GMA and TEGDMA.3 The direct resin equivalent, Filtek Supreme Ultra (3M), contains Bis-GMA, UDMA, TEGDMA, and Bis-EMA.3

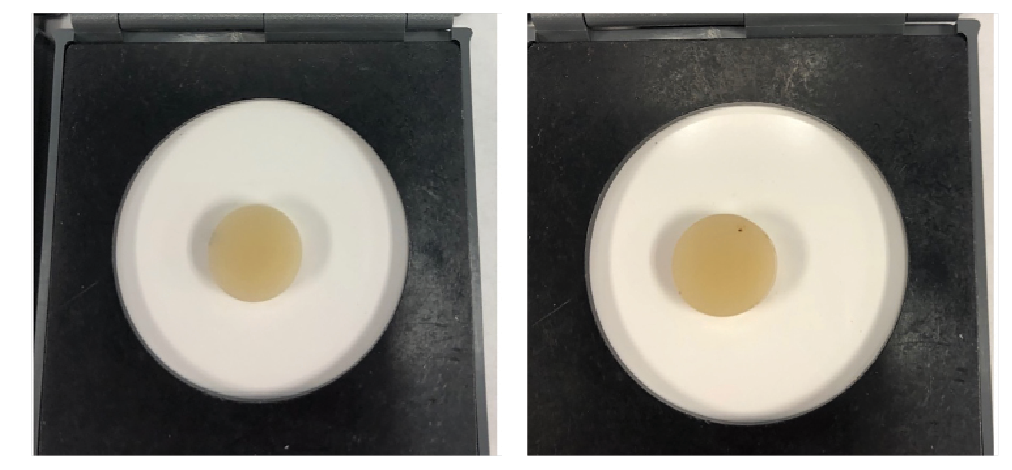

Figure 1. Paradigm MZ100 disk before and after 12 months of clinical staining.

The differences in staining susceptibility of direct and indirect composite resins has not been thoroughly investigated. Thus, it remains unclear whether prepolymerization or resin composition has a greater effect on stain susceptibility of composites. This study measured and compared the color change (∆E) of indirect composite restorative materials (CAD/CAM composite blocks) and direct composite restorative materials from the same manufacturer after immersion in wine.

The Products Tested

The following materials were compared: Tetric CAD and Tetric EvoCeram (Ivoclar Vivadent), Paradigm MZ100 and Filtek Supreme Ultra (3M), Grandio bloc and GrandioSO (VOCO America), and SHOFU Block HC and Beautifil II (SHOFU). VITA Enamic (VITA North America) was also included in this comparison because of its unique composition (86% wt feldspar ceramic, 14% wt polymer [UDMA, TEGDMA]5) and staining properties relative to the other materials tested. CAD/CAM composite blocks were sectioned to obtain 2-mm- and 4-mm-thick disks. Direct composite materials were layered using PVS molds in 1-mm composite increments, curing between each segment with a VALO UV curing light (Ultradent) between 2 glass microscope slides to obtain 2-mm- and 4-mm-thick disks. All sample groups were immersed in wine for 12 days at 37 °C, equivalent to 1 year of clinical staining (24 hours in vitro = 1 month in vivo).1

Color parameters (L*a*b*) and tooth shade were measured before and after exposure to the staining solution (Figure 1) using 2 instruments: a BYK-Gardner Color-Guide 45/0 (Figure 2) and Vita Easyshade colorimeter. Measurements were taken against separate black and white backgrounds with samples rotated at 0°, 45°, and 90°. ∆E values were calculated using the following equation: ∆E = [(L1*-L2*)2 + (a1* - a2*)2 + (b1*-b2*)2]1/2.

Figure 2. BYK-Gardner Color-Guide 45/0 used to measure color parameters (L*a*b*) on standardized black and white backgrounds.

The Results

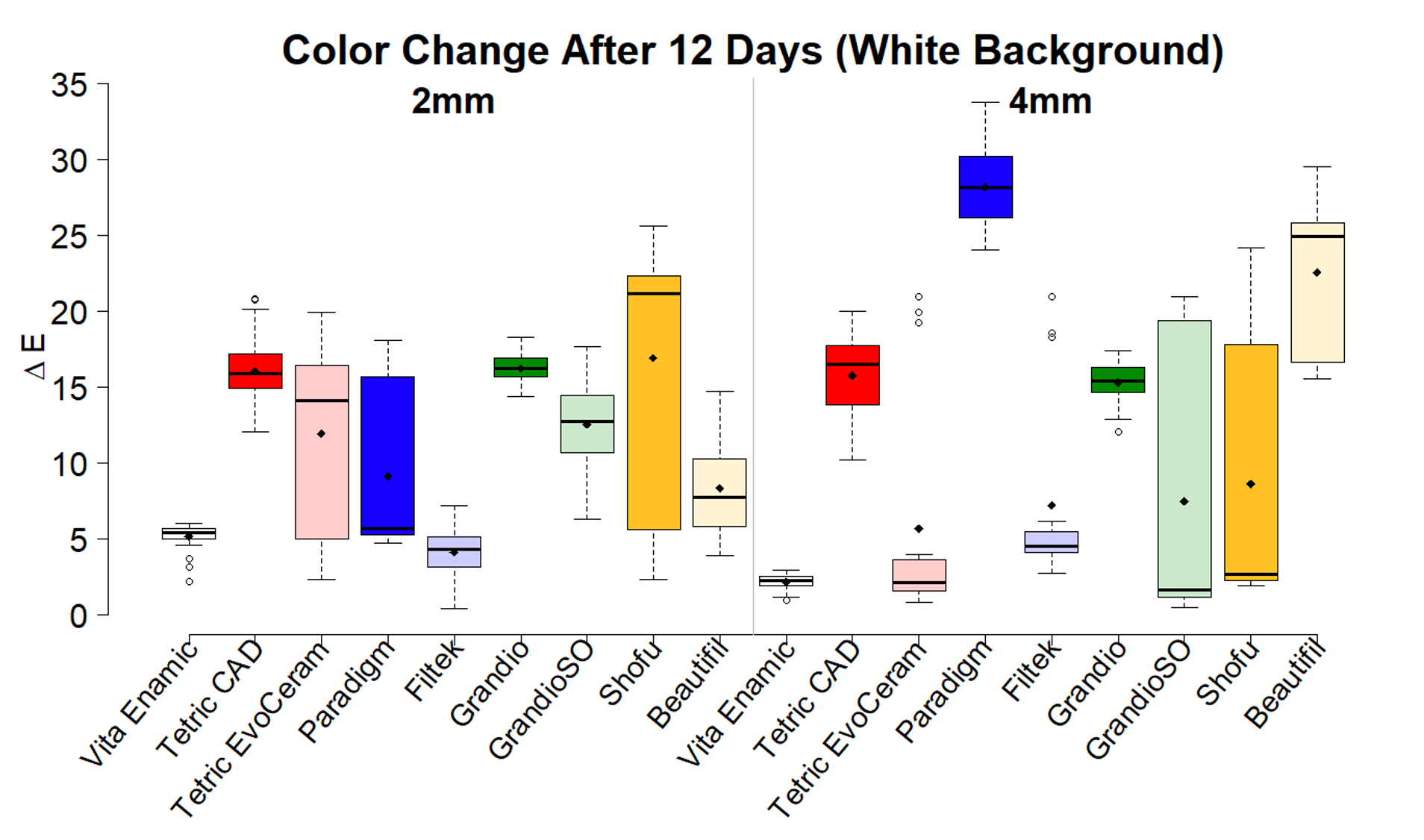

Three of the 4 indirect CAD/CAM blocks tested (Ivoclar Vivadent, 3M, and VOCO) had greater color change and more significant staining (larger ∆E) than their direct resin analog after 12 months of simulated staining (Figures 3 and 4). This suggests that certain indirect materials are more susceptible to staining agents than direct composite resin analogs. The results of this study suggest that the prepolymerization step in the manufacturing process of CAD/CAM composite blocks does not prevent staining. Furthermore, composite composition also played a significant role in staining.

Figure 3. Color change (∆E) after 12 clinical months of staining on the standard

white background.

Discussion

Discoloration of composite restorations is caused by the absorption of pigment from food and beverages. Staining susceptibility is related to water sorption of composite resin materials.3-5 Composite materials containing Bis-GMA have higher water sorption1,3,4 and thus increased susceptibility to staining agents. In this study, all direct composite resins contained Bis-GMA. The indirect materials containing Bis-GMA that were included in this study, Paradigm MZ100 and Tetric CAD, both showed higher ∆E values compared to their direct composite analogues. VITA Enamic, however, does not contain Bis-GMA 3,6 and showed the least amount of color change overall.

Recent studies have shown that CAD/CAM composite resin blocks are susceptible to staining. Bahadir and Bayraktar5 found that Lava Ultimate and VITA Enamic showed significant staining after 14 days in coffee solution (∆E = 4.975 and ∆E = 3.57, respectively). Barutcugil et al7 compared staining of Lava Ultimate (3M), Cerasmart (GC America), and VITA Enamic CAD/CAM blocks in wine and coffee at 24 hours (1 month clinical staining) and 30 days (2.5 years clinical staining). Red wine caused a larger color change than coffee.7 After 1 month of immersion in red wine and coffee, the materials tested showed a greater ∆E than clinically acceptable.7 The results from these studies indicate that CAD/CAM composite resins are susceptible to staining.

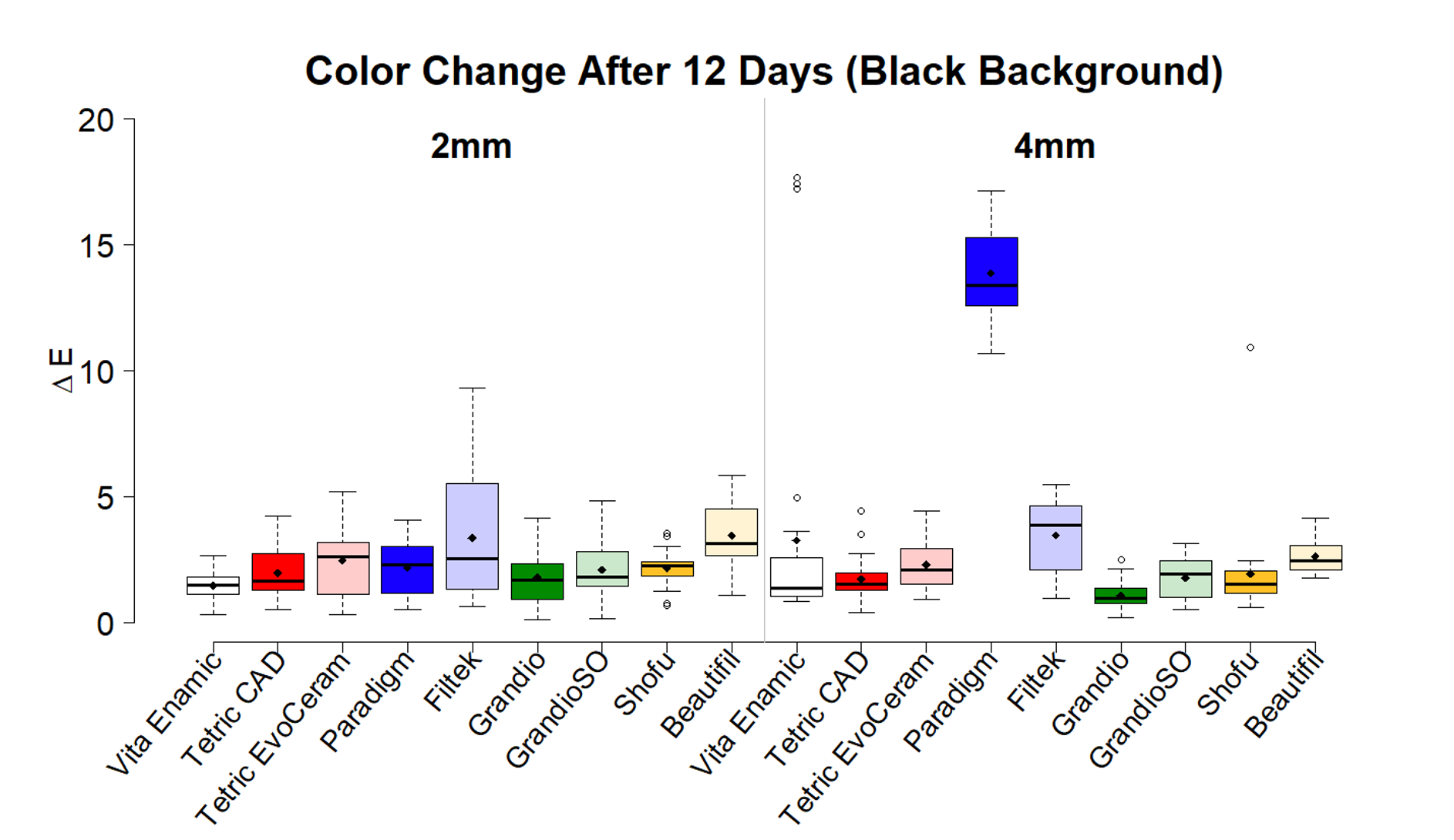

Figure 4. Color change (∆E) after 12 clinical months of staining on the standard

black background

The results from the current study suggest that certain composite materials may not be indicated for esthetic restorations. It is also important to note that there is a significant difference in ∆E values on white and black backgrounds because of increased light absorbance on black backgrounds. White and black backgrounds are clinically relevant, because they simulate different environments. White backgrounds simulate a clinical condition where there are preparation walls, such as a Class I, II, III, or V.3 Black backgrounds simulate anterior restorations such as a Class IV where more light absorbance may occur.3

Color change is visible to the naked eye when ∆E is greater than or equal to 3.3.6 Most materials showed a ∆E less than 3.3 on the black background with the exception of Paradigm MZ100, Filtek Supreme Ultra, and Beautifil II. Therefore, many of these materials could be considered appropriate for anterior Class IV restorations, because the results of this study indicate the color stability of these materials after 1 year of simulated clinical service.

Interestingly, a Class I, II, III, or V composite restoration would show significantly more stain over time because of the number of cavity walls surrounding the restoration. In Figure 3, indirect and direct composite resin materials had significant staining after 1 year (∆E > 3.3).

The staining is significant enough that a patient could notice a difference in a period of 6 months to 1 year. Therefore, it is crucial to choose a composite resin material wisely, whether it is an indirect or direct restoration, to ensure patients receive esthetic restorations that maintain their ideal color properties over time.

Conclusion

In this study, the null hypothesis stating that CAD/CAM composite stainability is not higher than direct composite resin was rejected. Three of the 4 CAD/CAM blocks tested (Ivoclar Vivadent, 3M, and VOCO) had larger color change and more significant staining (larger ∆E) than their direct resin analogue. Thus, discoloration of both direct and indirect composites is related to composite composition. Composites with higher water sorption will have increased staining over time, whether it is a direct or indirect material.

It is clear that clinicians must be mindful of color change in restorations, especially for patients with high esthetic expectations. After 1 year, all materials tested showed a ∆E greater than or equal to 3.3 on the white background except for VITA Enamic. This indicates that a color change would be visible to the naked eye if the composite materials were used for a Class I, II, III, or V restoration. The black background, on the other hand, simulates a Class IV restoration. Many of the materials tested would be suitable for this situation, because color change was not significant to the naked eye (∆E > 3.3). Appropriate composite material selection is crucial for long-term esthetic success of restorations. ●