How to maintain dental unit waterlines

Consider desired workflows and product-use protocols when choosing a waterline maintenance approach.

In recent years, dental practitioners have become more cognizant of microbiological contamination of dental unit waterlines. Due to the nature and complex design of dental delivery units - and because even low levels of bacteria commonly present in waterlines can increase exponentially very quickly - the periodic use of waterline cleaners and antimicrobials is extremely important for proper dental waterline care.

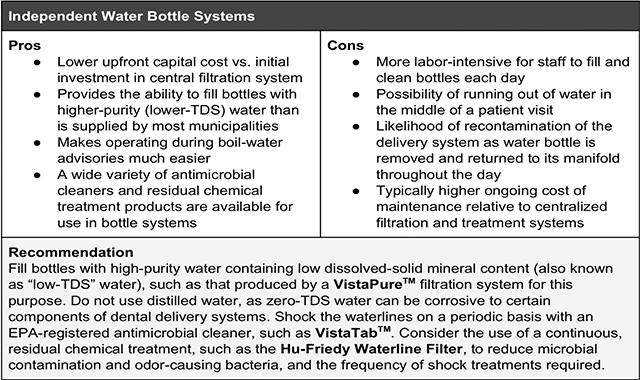

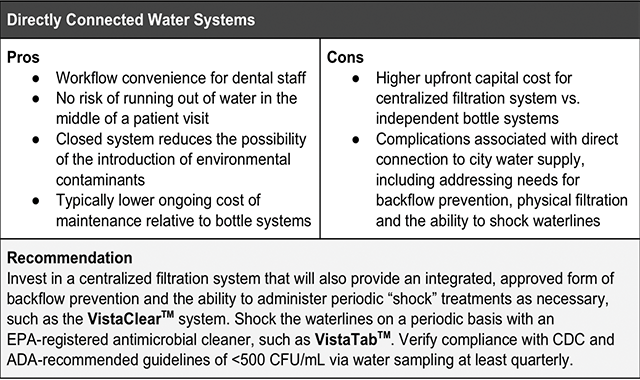

Various efficacious methods of waterline maintenance exist. Whether water is delivered from a dental bottle or a direct connection to the delivery system, maintenance approaches have trade-offs that dental practitioners should consider when making decisions about how to treat their waterlines to protect their patients, staff and equipment.

The problem with dental unit waterlines

The problem of microbial contamination in dental unit waterlines is the result of how water is used during routine dentistry and the design of the dental equipment itself. Factors including small-diameter waterlines, low flow rates, long periods of stagnation, improper waterline termination, and even occasional backwards contamination from the patient to the delivery system all contribute to microbial contamination.

The unfortunate reality is that even quality input water can quickly become contaminated in dental unit waterlines. Even a single microorganism that survives filtration and chemical treatment can replicate exponentially. As such, microbiological contamination of dental unit waterlines is a challenging issue that must be addressed rigorously.

Dental bottles and direct connections

Years ago, in an attempt to combat this contamination issue, dental delivery system manufacturers introduced independent bottle systems. These bottle systems provide delivery units with an independent source of water not connected to the city water supply and typically hold between 750 milliliters to two liters of water.

The basic line of thinking with these systems was essentially that more control over the quality of the input water to the system via independent bottles would enable higher quality output water. While this idea sounded very reasonable in theory, it wasn’t sufficient in practice without proper cleaning and maintenance of dental bottle systems.

Even returning a dental bottle filled with otherwise sterile water to its manifold can introduce contamination. Airborne bacteria and microbes present on the surface of the riser tube reinserted into the bottle can instantaneously introduce contamination back into the system. Furthermore, regardless of how the water is delivered, the bacteria will eventually recolonize the water within the system, regardless of delivery methods.

To avoid complications with bottle systems, some practitioners choose to plumb their delivery units directly to the city water supply, but this method can also prove to be a challenge to finances and quality. For instance, many local plumbing authorities disallow direct connections to the public water supply without expensive backflow prevention devices installed for each operatory. Furthermore, some dental practices may have trouble paying for the mandatory shock treatment that will need to be administered to direct waterlines. Regarding quality concerns, city water often contains sediment, scale and fine particulate matter that can harm dental equipment.

Continue reading on page 2...

Dental waterline maintenance protocols

Whether dental operatories are plumbed directly to municipal water supply lines, utilize independent bottle systems, or have a water filtration system installed, the following protocols and guidelines should be observed at all times for dental waterline maintenance:

- Discharge air and waterlines for a minimum of 20-30 seconds after each patient, as recommended by the Centers for Disease Control and Prevention (CDC). This procedure is intended to flush out patient material that might’ve entered the handpiece turbine, air or waterlines.

- Don’t use waterline heaters, as they serve to increase the growth rate of any microorganisms that might be present in the lines tremendously.

- Never use water from a standard dental delivery system during surgical procedures. Instead, use sterile water or saline delivered by sterile means, such as autoclavable bulb syringes or autoclavable or disposable sterile tubing.

- Monitor water quality throughout the operatory environment at least quarterly by submitting water samples to a laboratory for heterotrophic plate count (HPC) testing, or by using an in-office testing product, to ensure compliance with water-quality standards of <500 colony-forming units (CFU) of bacteria per milliliter, as recommended by the CDC.

Further, if using any type of water filtration system - whether plumbed directly to the dental delivery unit or for filling dental bottles - it’s important to follow the manufacturer’s Instructions for Use (IFU).

Product considerations and trade-offs

Considering all the challenges associated with dental unit waterline maintenance and the various types of products available intended to address these challenges, it’s understandable why many practitioners have trouble determining the best approach for their practice. Several viable approaches to dental unit waterline maintenance exist, including periodic shock treatments and daily maintenance products, depending on whether the practice is using dental bottles or direct water connections.

Shock treatments are necessary to decontaminate waterlines. Strongest treatments are administered when water lines are first installed, followed by periodic applications of concentrated antimicrobial agents to cleared water lines.

EPA-registered shock treatments include a liquid form and also a tablet. In choosing the form of shock treatment that’s best for a practice, it’s important to consider the instructions for use and how these instructions “fit” the practice’s desired workflow. For instance, one type of shock treatment must be left in the lines overnight and used for three nights in a row for an initial treatment. Another product option is noncorrosive and only needs to be left in the waterlines for five minutes before being purged and rinsed with fresh water. Regardless of the type of shock treatment chosen, it’s important to verify the compatibility of the product with the manufacturer of the dental delivery equipment and to use the product(s) according to the manufacturer’s instructions.

While it’s possible for practices to maintain water quality in compliance with the CDC recommendation of <500 CFU/mL using only periodic shock treatments, most waterline protocols require a two-part approach that involves both periodic shocking and a daily maintenance product. These maintenance chemicals are safe when used appropriately and can help to control contamination continuously when used as a residual treatment in the waterlines.

Daily maintenance products are available in different forms, including liquid, tablets and cartridge-style filters for in-bottle or inline use. The most commonly used chemicals for daily maintenance include silver-based compounds and elemental iodine. As with shock treatments, it’s important for practices to consider the various products’ instructions for use, workflow convenience and ongoing cost.

Like shock treatments, different forms of daily maintenance products and their respective active ingredients have trade-offs. For instance, tablets must be used every time a water bottle is filled, whereas cartridge-style filters typically last up to a year before replacement is necessary.

Silver-based products can combine with dissolved solids in water to form precipitates known as “silver salts” that can clog valves inside delivery systems and stain water bottles. Iodine-based products can also stain bottles and sometimes impart a slightly astringent taste to process water, although this is usually not noticeable, especially when used with high-purity water.

Continue reading on page 3...

Summary and recommendations

As previously stated, due to the nature and complex design of dental delivery units, the periodic use of waterline cleaners and antimicrobials is extremely important for proper dental waterline care. The choice of which products to use must be reached by considering the practice’s method of water delivery as well as the staff’s desired workflow and willingness to comply with shock treatment and daily maintenance products’ instructions for use.

In my opinion, based on nearly 40 years in the water treatment industry and almost 20 years in dentistry, the best input water is filtered to be free from particulates and purified to contain low dissolved mineral content (TDS). Distilled-quality (zero-TDS) water shouldn’t be used in dental delivery systems since this water is actually corrosive to certain components of delivery systems over time.

Shock treatments are absolutely necessary upon system installation and periodically thereafter, if microbial content ever exceeds 500 CFU/mL. For daily maintenance, I’ve found that many practices prefer the convenience of cartridge-style filters that only need to be replaced annually, as opposed to daily tablets that must be used upon each bottle filling. Finally, I prefer the use of elemental iodine to silver-based compounds.