How one workflow is improving dental milling

Digital Esthetics explores how the SMARTMill51D workflow from ETI Digital Technology improves dental milling and final outcomes.

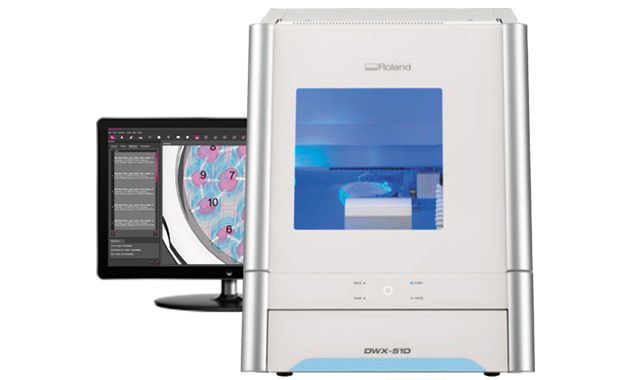

Combining the milling capabilities of the Roland DWX-51D five-axis mill with the advantages offered by UNIQUE CAM software, the SMARTMill51D system from ETI Digital Technology is designed to provide detailed and efficient milling solutions for every dental laboratory.

The SMART (which stands for Smart Manufacturing Adaptive & Reliable Technology) workflow provides milling capabilities for a large variety of indications, including partiatls, bite splints, surgical guides, crown and bridge models and more. The five-milling axes of the DWX-51D allows for fine control over margins and results. The 10-station tool changer helps the mill achieve stunning detail, and the UNIQUE CAM software allows even greater control over tool choice.

The other half of CAD/CAM: ETI Digital Technology's scanning solution

The UNIQUE CAM software is also designed to allow users to ensure they’re using every puck of digital material to its fullest extent. The purchase price of the system includes three years of software updates and maintenance, along with ETI Digital Technology’s customer service and support. For more information, visit etidigitaltechnology.com or call 800-451-7778.

Other features include:

- A vacuum and anti-static ionizer for better calibration and dust reduction

- Ability to interconnect as many items as can be placed on a disc

- PDF file for ease of locating cases post-milling

- Different milling strategies for different materials, designed to increase tool life

User testimonial

We are pleased with ETI Digital Technology’s overall customer service as purchasing our complete CAD/CAM system has been a life- and game-changer for us! We can literally mill everything we want in-house, everything from their Dental Wings 7Series Scanner to the Roland DWX-50 milling machine with Unique CAM software has been wonderful. We had been wanting to get into CAD/CAM for a long time and our purchase from ETI Digital Technology was one of the best decisions that we’ve made for our laboratory’s overall production and growth. We could not ask for more on the products that we had purchased and the continual customer support that we receive. ETI’s Technical Director, John Just, traveled to our laboratory and provided an excellent and thorough training session on the equipment and software that we purchased, which further supported our decision to purchase from ETI.”

- Dorothy & Mark Edwards // Owners of Main Street Dental Laboratory // Hiawassee, Georgia