How to use digital technology to improve patient care

A day in the life of a digital dentist.

A dental practice in the United States is largely comprised of private practitioners whose attention given to mastering clinical skills often outweighs attention to mastering business skills.

The in-roads being made in dentistry by corporate entities place a strong spotlight on the differences of approach in dental practice when the business of dentistry is given equal weight to clinical skills. Practices that place equal emphasis on business strength have a strong advantage in all areas of the dental marketplace-especially with respect to delivering higher levels of patient care.

The long-time president, chairman and CEO of General Motors Corporation Alfred P. Sloan in his book My Years with General Motors wrote, “The big work behind business judgment is in finding and acknowledging the facts and circumstances concerning technology, the market and the like in their continuously changing forms. The rapidity of modern technological change makes the search for facts a permanently necessary feature.”

In 1999, Microsoft founder and CEO Bill Gates wrote his revolutionary book Business @ The Speed of Thought. In it he stated, “I have a simple but strong belief. The most meaningful way to differentiate your company from your competition, the best way to put distance between you and the crowd, is to do an outstanding job with information. How you gather, manage and use information will determine whether you win or lose.”

If the words of these two giants in American business are true-that the continual search for advanced technology is key, and that the implementation of that technology is necessary to maintain competitive advantage - then it’s reasonable to assume that it would be important to understand the state of advanced technology in dentistry today by seeing what is not only possible but routine in technologically advanced dental practices.

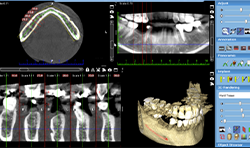

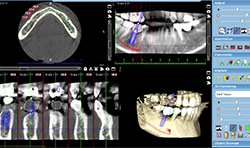

Patients routinely come to the office for consultations regarding the placement of dental implants for missing teeth. An ultra-low dose dental cone beam computed tomography image (ULD CBCT) is the only image taken during the consultation. The image shows all of the required information for answering the patient’s questions, for determining whether the patient is a candidate for implant placement and for virtually planning the implant.

A 39-year-old female presented as a new patient for an implant consultation to replace missing tooth #30. A ULD CBCT (Figs. 1-2) was taken, and it was determined the patient was a candidate for implant placement.

Fig. 1

Fig. 2

Fig. 1

A review of the scan revealed no pathology. The bone appeared to be dense with adequate width. The mandibular nerve was drawn, showing the nerve and the foramen were safely inferior to any position the implant would be placed.

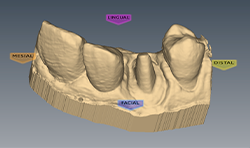

Using Planmeca Romexis® software, the appropriate implant library was selected, and a Camlog iSY 4.4x13-mm implant was placed virtually, along with an abutment and library crown to help visualization of proper implant angulation.

From this consultation, the patient agreed to treatment and became a patient of the practice. She scheduled a new patient examination and hygiene appointment and scheduled surgery for the implant placement.

Trending article: Using technology for better esthetic outcomes

A surgical guide was printed from the implant scan. The Romexis cone beam study is transferred within Romexis to the Romexis Surgical Guide Module, where a surgical guide is designed for implant placement (Figs. 3-6). The stereolithography file (STL) for the design guide was then downloaded to 3D printer software to print the surgical guide in-house on the practice’s 3D printer.

Fig. 3 Fig. 4

A day in the life of a digital dentist doesn’t pass without digital impressions utilizing a scanner and milled fabrication of restorations. Fabrication may be accomplished in-house in a single appointment or by a laboratory from the digital scan impression.

Fig. 5 Fig. 6

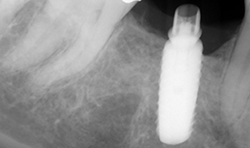

The implant in the tooth #12 area on the 50-year-old female patient is ready for restoration. In this instance, a stock abutment was selected and prepared extraorally. The abutment was placed to 25 ncm torque.

The PlanmecaFit with the Planmeca Emerald™ scanner (Figs. 7-8) was used to take a set of digital impressions, and the restoration was milled in the PlanMill® 40 S using an Ivoclar Vivadent IPS e.max block shade A1.

Fig. 7

Fig. 8

Fig. 7

Continue reading on page two...

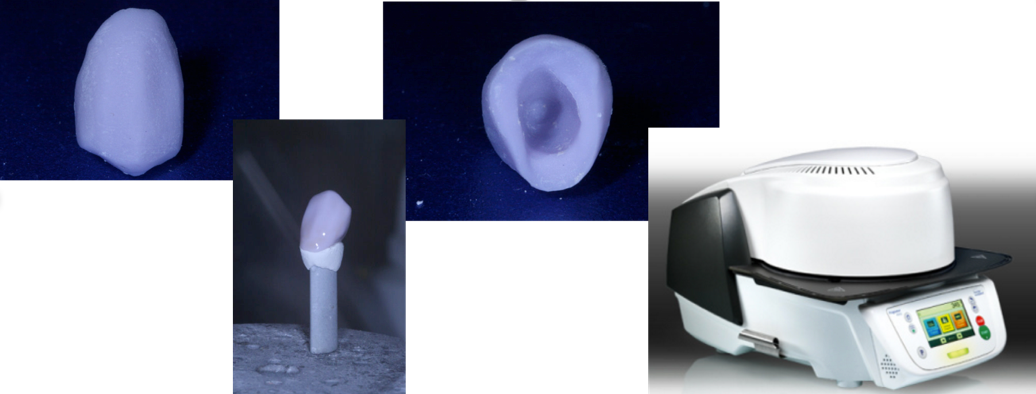

The milled restoration (Fig. 9) was crystallized and glazed in an Ivoclar Vivadent Programat CS2 oven.

Fig. 9

Figs. 10-11

Fig. 9

The restoration was seated (Figs. 10-11), contacts and occlusion checked, and luted into place with Ivoclar Vivadent SpeedCem composite luting cement.

Finally, a day in the life of a digital dentist isn’t complete without a same-day restorative case. Digitally scanned impressions allow for the consistent, accurate, comfortable and cost-effective production of restorations.

A 46-year-old male patient presents with pain on tooth #6. He stated he was traveling overseas in four days for an extended period of time and would like treatment to be completed.

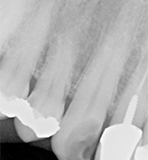

A digital periapical X-ray (PA) (Fig. 12) was taken using Air Techniques ScanX phosphor plates. The PA revealed caries into the pulp. The tooth would require endodontic therapy, a post core and a crown.

Fig. 13

Fig. 12 Fig. 13

Root canal therapy was completed (Fig. 13).

A carbon fiber post and composite core buildup was completed (Fig. 14), and a soft tissue crown lengthening was performed with a diode laser at a setting of 2W continuous pulse mode.

Fig. 14

Fig. 15

Fig. 14 Fig. 15

A digital scan (Fig. 15) was taken using the Planmeca Emerald. The total scan time of the preparation, the upper arch and the lower arch was less than two minutes.

An IPS e.max CAD block low translucency shade A2 was milled in the PlanMill 40 (Fig. 16). Milling time was 14 minutes.

Related reading: An all-in-one solution to streamline dentistry

The milled crown was tried in the patient’s mouth and contacts and occlusion were adjusted. The crown was cleansed and dried and prepared with e.max stains and glaze prior to an approximately 20-minute cycle in the Ivoclar Oven (Fig. 17).

Fig. 17

Fig. 16

The final crown (Fig. 18) was seated and cemented with Ivoclar Vivadent SpeedCem cement. The total treatment time for this case was three-and-a-half hours from start to completion.

A day in the life of a digital dentist is a fulfilling and satisfying day in terms of the high level, sophistication and variety of care that can be accomplished, not to mention the high degree of profitability afforded.

The search for optimal advanced technology is a never-ending quest; however, it’s an essential ingredient that’s required for success in today’s economic and practice environment.

Fig. 18

To paraphrase Bill Gates, the most meaningful way to differentiate your practice from others in the eyes of your patients, and the best way to put distance between you and the crowd, is to do an outstanding job with advanced dental technology. How you use advanced technology to gather and manage information and to provide care will determine your level of success in this profession.