How to create highly esthetic monolithic zirconia crowns in 8 simple steps

3M ESPE’s Lava Plus High Translucency Zirconia offers both outstanding esthetics and strength.

3M ESPE’s Lava Plus High Translucency Zirconia offers both outstanding esthetics and strength.

In 2002, a zirconia-based ceramic system was introduced that used CAD/CAM technology to produce high-strength zirconia copings that could then be overlaid with stacked or pressed porcelain (Lava Zirconia from 3M ESPE). This technology provided clinicians with a viable alternative to traditional porcelain fused to metal (PFM) restorations.

A potential problem surfaced when some reported excessive chipping and/or fractures of porcelain that was layered over the zirconia substructure.1,2 This appeared to be largely because of poor coping design and the fact that zirconia requires very specific parameters regarding heating and cooling cycles during fabrication, to which some labs did not adhere. Once these issues were recognized and addressed, any chipping issues were significantly attenuated. In any case, the emergence of full-contour monolithic zirconia restorations has made this a non-issue, as these restorations are milled from a single block of zirconia and there is no stacked or pressed porcelain that has the potential to chip. Monolithic zirconia fixed partial dentures (crowns) have many potential advantages, including very high flexural strength, the ability to be conventionally cemented or bonded into place, the benefits of CAD/CAM technology, and the fact that they are generally less expensive than traditional PFM restorations.

Two popular full-contour monolithic materials used for single fixed partial dentures are zirconia and lithium disilicate. While zirconia offers significantly greater flexural strength (more than 900 MPa compared with 400 for lithium disilicate), lithium disilicate has generally been considered to be a better choice for use in the esthetic zone because of its greater translucency and a more natural appearance. However, a new zirconia material now offers significantly improved esthetics as well as the strength for which zirconia is known. 3M™ ESPE™ Lava™ Plus High Translucency Zirconia is based on the original Lava™ Zirconia, with new special chemistry and processing to enable more translucency and warmth, and more natural esthetics.

A zirconia’s translucency is influenced by two main factors: the presence of impurities and structural defects, and the alumina distribution and content. Alumina is added to some zirconias to maintain aging stability, but it can decrease translucency by scattering light. To engineer Lava Plus zirconia for both excellent aging stability and translucency, 3M ESPE reduced the alumina content in the material to 0.1 percent of its weight. The distribution of the alumina also was improved, along with other high-quality processing steps to fully optimize the material’s translucency.

Custom shading capabilities

In addition to its excellent translucency, Lava Plus zirconia has a unique shading system that gives laboratories many options for custom shading and characterization. After milling a porous green-state block, the laboratory can choose from among 18 dyeing liquids that cover the 16 Vita Classical A1-D4 shades, as well as two bleach shades, to achieve custom coloring. (Lava Plus zirconia is the only system that matches the Vita Classical A1-D4 and bleached shades.) The dyeing liquid is applied and then, during the sintering step, the color ions are incorporated into the zirconia. This technique was invented by 3M ESPE, and because the dyeing liquids are designed specifically for the zirconia, dentists and labs can be assured of an excellent color match to the Vita Classical shades. When using a zirconia system without this dedicated shading system, labs must use a process of trial and error to achieve the desired color match, which decreases efficiency as well as compromises esthetics.

While this zirconia offers excellent performance as a monolithic material, traditional layering also can be done, giving dentists and labs versatile options for achieving their esthetic goals. Whether it is used in a monolithic restoration or layered, field evaluations have shown that dentists and labs prefer the esthetics of this zirconia to many other zirconia systems, with data showing it offers significantly higher all-zirconia crown translucency.3,4

Added benefits of greater strength

The greater strength of zirconia as compared to lithium disilicate also enables dentists to preserve tooth structure during preparation. Lava Plus zirconia crowns require only 0.5 mm minimum occlusal clearance while lithium disilicate ideally should have 1.5-2 mm of clearance. This difference can be significant in posterior applications where space is often tight. With significantly greater strength and now improved esthetics, this high translucency zirconia has the potential to be used in either the posterior or anterior regions of the mouth.

The case illustrated on the next page highlights the use of this material to create a natural-looking crown for a first bicuspid.

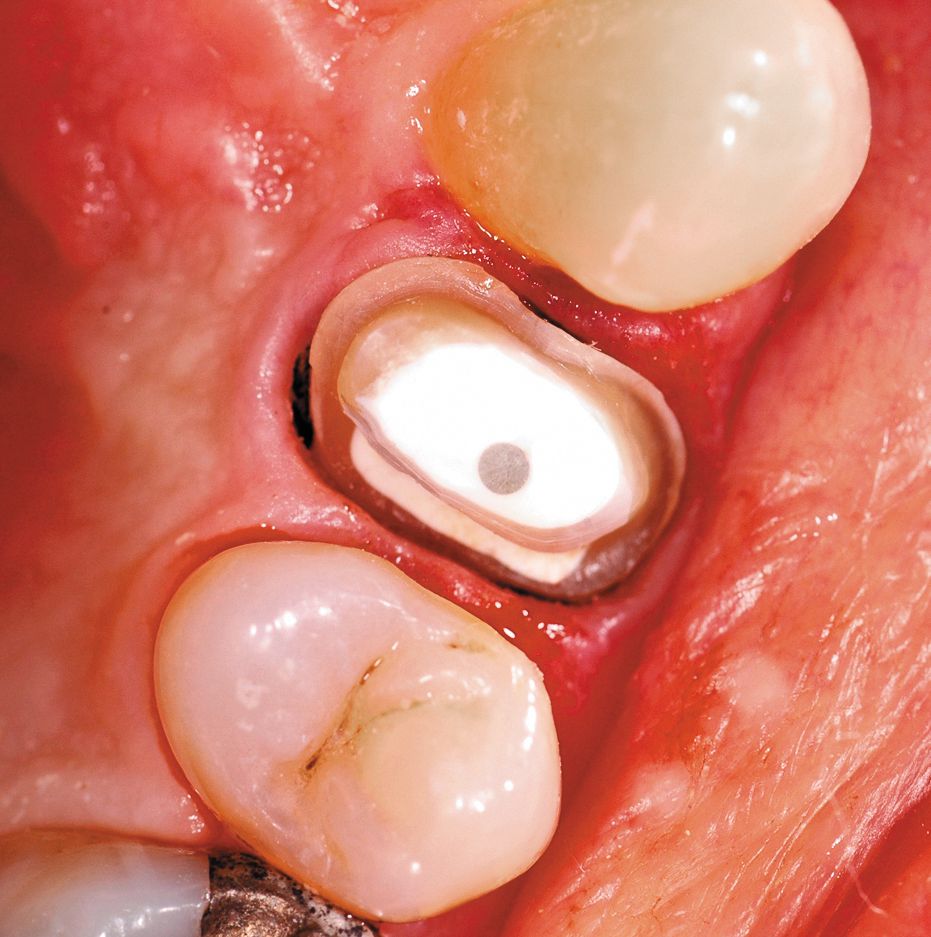

Step 1: The tooth was prepped with a rounded internal shoulder preparation. A deep chamfer preparation also can be used. It is important not to have sharp line angles and to smooth and round the occlusal aspect of the preparation (Fig. 1).

Figure 1: The preparation on tooth No. 5 following endodontic treatment, post placement and core buildup.

Step 2: An automixed (Pentamix 3) heavy and syringeable light body VPS (3M™ ESPE™ Imprint 3 Penta Quick Step Impression Material) was used to capture the impression (Fig. 2).

Figure 2: A fast-setting VPS impression material was used.

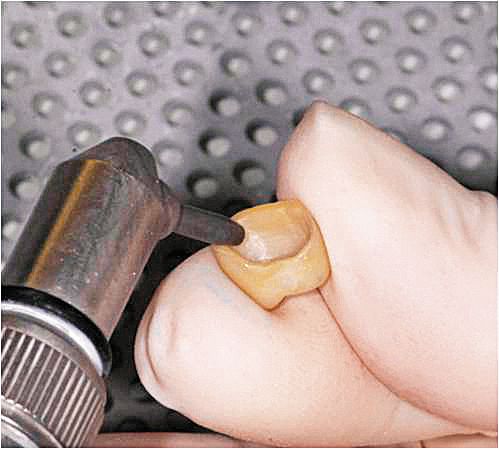

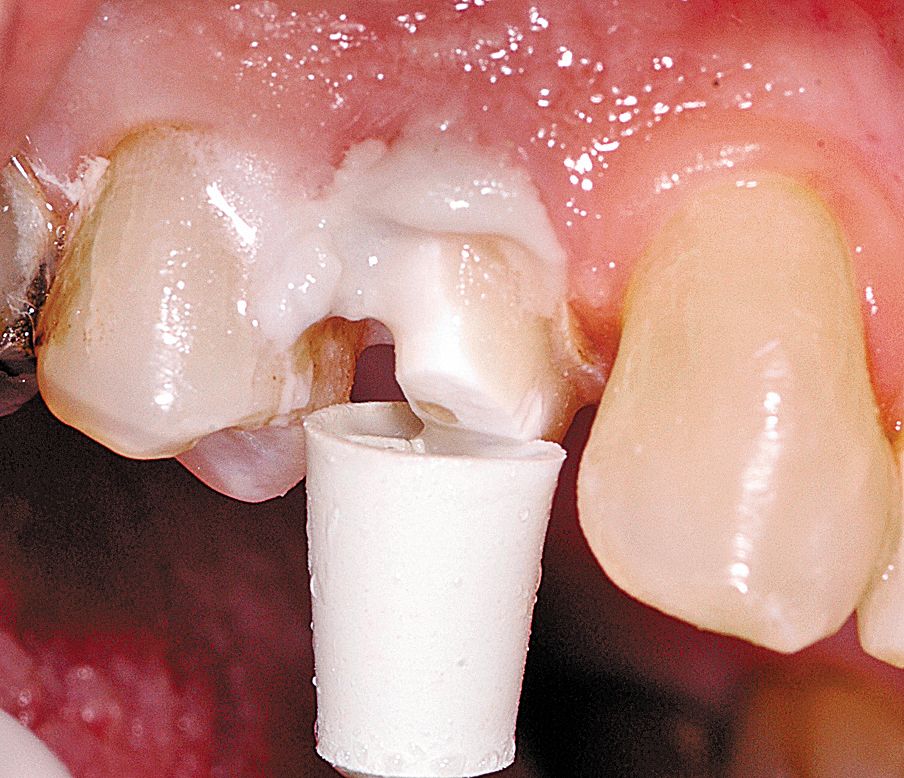

Step 3: The case was sent to the lab, along with photographs illustrating shading. The laboratory milled the crown using Lava™ Plus Dyeing Liquid to customize the shade (Figs. 3 and 4).

Figure 3: Finished die.

Figure 4: Finished monolithic crown made with Lava Plus Zirconia.

Step 4: The crown was returned to the office and tried in to confirm fit. The internal surface of the crown was lightly sandblasted, and the crown was rinsed and air dried (Fig. 5).

Figure 5: The interior surface was lightly sandblasted.

Step 5: Z-Prime Plus by Bisco was uniformly applied to the interior surface and dried with warm air for 5 seconds to improve the chemical interaction (Figs. 6 and 7).

Figure 6: Zirconia primer was applied.

Figure 7: The primer was dried with a warm air stream.

Step 6: The tooth was cleaned with a Pumice Preppie by Whip Mix (Fig. 8).

Figure 8: A disposable rubber cup with pumice was used to clean the preparation.

Step 7: 3M™ ESPE™ RelyX™ Luting Plus Resin-Modified Glass Ionomer Cement was dispensed onto a mixing pad and the two pastes were mixed together for 20 seconds. The cement was applied to the internal surface of the restoration (Fig. 9).

Figure 9: 3M™ ESPE™ RelyX™ Luting Plus cement was loaded into the crown.

Step 8: The crown was seated onto the preparation with light pressure. The pressure was maintained for several minutes during the setting process. Once the cement reached a waxy stage, excess material was cleaned away (Fig. 10). A diamond polishing paste was used to achieve the final finish.

The final result was a highly esthetic crown that blended perfectly with the surrounding dentition (Figs. 11 and 12).

Figure 10: The crown was seated and excess cement removed after four minutes.

Figure 11: Occlusal view of the final restoration.

Figure 12: The crown exhibited an excellent match to the surrounding area.

Closing thought

The simplicity of monolithic restorations makes them very attractive for dentists, but until recently they have had to carefully balance their needs for esthetics and strength to determine which material is most appropriate. The high translucency zirconia material used here illustrates the new capabilities of zirconia to deliver outstanding esthetics as well as strength. The material is offered with a 15-year warranty, and is based on the original Lava zirconia, which has an 11-year track record of reliability. With this high-translucency zirconia, dentists have an excellent new option for creating strong and natural-looking restorations that are guaranteed to last.

3M™ ESPE™ Lava™ Plus High Translucency Zirconia Features

• Patented shading system enables highly esthetic all-zirconia or traditionally layered restorations

• Excellent color match to the VITA Classical Shade Guide and VITA SYSTEM 3D MASTER Shades

• Offers both strength and beauty

References

1. Heintze SD, Rousson V. Survival of zirconia- and metal-supported fixed dental prostheses: a systematic review. Int J Prosthodont. 2010 Nov-Dec;23(6):493-502.

2. Swain MV. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2009 Jun;5(5):1668-77.

3. Application Test Lava™ Plus High Translucency Zirconia, 11 responding dental labs in Germany, Austria, Italy, Netherlands and U.S., 2011.

4. Application Test Lava™ Plus High Translucency Zirconia, 18 responding dentists in Germany, Italy and U.S., 2011.