Innovator Profile: BEGO

Innovation drives our profession and DLP wants to recognize the companies at the forefront. In this Innovator Profile, DLP spoke with Nick Azzara, Chief Sales & Marketing Office of BEGO USA about how BEGO is shaping the industry.

Q: How is BEGO shaping the industry?

A: BEGO is recognized as a global leader for dental lab materials, implants and CAD/CAM production. Here in the U.S., we have applied that deep BEGO know-how from our parent company and have matched it with incredibly skilled people in client services, digital workflow management, traditional dental technology and digital design software.

Webinar: Learn the real value of 3D printing in the dental lab

Q: How has SLM technology changed the workflow?

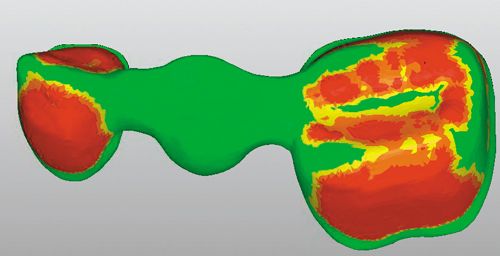

A: Milling offers terrific promise for efficient manufacturing. At BEGO, we have very unique milling strategies to make sure our output meets our expectations. Yet, even though we are highly involved in milling, our additive manufacturing process of Selective Laser Melting Non Precious and Noble frameworks is absolutely living up to the promise of quality, fit and performance we have set. SLM metals have so much potential because the process is faster and much more cost-effective. BEGO has developed an exclusive partnership with the EOS company in North America. EOS makes the SLM machines and is the leader in metal printing technology for all industries, not only dental.

Q: What makes BEGO’s SLM material offerings unique?

A: BEGO has a long history with Chrome Cobalt metals. Certainly this is an advantage. Yet, equally as important is the focus that BEGO has placed into data preparation and software development with SLM over the past 12 years. The BEGO process takes every file submitted to BEGO and runs it through an auto quality control (QC) software, and then optimizes the file for the SLM process. The end results are restorations that are accurate, stable and dense. If a file is not suitable for SLM for some reason, our Advanced Data Management Team is on the phone with clients within 20 minutes of file submission to help make it right. It is an added bonus that the SLM metals have superior physical properties than traditionally cast metals and are extremely bio-friendly. Bio-friendly materials help our profession as a whole to build patient trust.

Q: How does BEGO help labs with more traditional methods of metal work?

A: In the BEGO production center, we also offer CAD/cast options. All of our castings are invested with BEGO Belavest SH, under pressure in the Wiropress and casted with the Nautilus induction/vacuum machines; no torch casting. The BEGO process ensures the metals are casted optimally. It has always been frustrating for labs to fully depend on consistency of torch casting. If casting plays any part within the lab’s business model, even if it is a small and decreasing part, BEGO materials, the Wiropress and the Nautilus are worth the investment. The Nautilus machine allows the lab to take complete control of the casting process, of the density of the metal and the consistency. It’s a huge benefit.

Q: How does BEGO work with labs to make sure they stay up-to-date on changing trends in the alloy world?

A: Under the guidance of our president, Lou Azzara, we’ve taken a very proactive approach to help labs succeed in any economic environment. We believe labs will be able to implement more technology, if they so chose, as machinery prices come down. Whether labs should invest in marketing, infrastructure, people, technology, or any combination of these factors, and whether they need to source all or part of their production, BEGO is equipped to help. At BEGO, we have the systems, array of materials, and highly qualified team to help labs make good decisions with data management, software designs and restoration selection. At the end of the day, we enjoy surprising clients with our service, great products, quality, turn times and fair pricing.

Trending Article: One Year Later: 15 products that have made a difference

Featured Brands

SLM Technology

provide a reliable method for flat-fee, cost-effective PFM frames. From single units to long span bridges and Tertiary frames over implant bars, BEGO SLM is an option that many labs can leverage.

Milling Capabilities

The BEGO production center mills trusted brands, including IPS e.max® CAD (Ivoclar Vivadent) and BruxZir® Solid Zirconia (Glidewell Laboratories), in addition to many other quality materials. Front-end QC matched with unique BEGO milling strategies assures a higher level of quality and consistency.

Data Management

From the Proprietary BEGO “Optimization Process” or “Auto QC,” to the Case Tracker App that manages cases from the convenience of your cell phone, BEGO is truly an extension of a lab’s in-house manufacturing. The BEGO Team called Advanced Data Management is knowledgeable in 3Shape, exocad, Dental Wings and other popular software programs and can help labs overcome any challenges.

Nautilus CC Casting Machine

For the most consistent, dense and perfectly melted castings, the Nautilus CC+ is the answer. Each alloy is programmed to cast at the perfect melting temperature in this self contained table-top model. The induction/vacuum Nautilus CC+ minimizes oxidation and casts the most predictable frames for both small and large cases.

This article originally appeared in the July/August 2014 issue of DLP.