Bench mastery: Ideal, natural-looking restorations

One Shot Uni-Layer HT has the potential to increase your laboratory’s productivity exponentially by speeding up your initial buildup to just minutes, all while producing an ideally natural-looking restoration.

One Shot Uni-Layer HT has the potential to increase your laboratory’s productivity exponentially by speeding up your initial buildup to just minutes, all while producing an ideally natural-looking restoration.

One Shot porcelain and press pellets for both ZR and MP confidently provide strong zirconia, metal or all ceramic-based restorations for crowns and large span bridges in the anterior and posterior regions without limitation. Go even further, creating all-ceramic veneers, inlays and onlays, making it an extremely versatile and aesthetic material.

The specific shade opaque selected will determine the final shade of the restoration. The transmission of the specific shade is due to the opalescent nature of One Shot, which reflects the light just enough to create a natural looking restoration, while also providing ideal translucency in the incisal and cervical areas. The ultra-fine micro porcelain is adapted to the diffused light reflection of natural enamel and dentin. The light optical properties of natural teeth are simply reproduced and, in the case of metal restorations, the contours of the metal frame are completely minimized.

One Shot is a material which resists absorption of moisture, reducing degradation of the porcelain finish and abrasion to the opposing dentition. The characteristics of the opalescent blend powder provide consistent, perfectly matched results each and every time.

Video: Q&A: Jim Collins on Shofu's OneShot Uni-layer and Veracia denture material

Ceravety Press and Cast was used to invest the press material. This universal investment is formulated for use with press ceramics and casting alloys using the ringless investment method. Suitable for use with non-precious and precious alloys as well as press ceramics, the investment features a 6-minute working time and a 20-minute quick burnout. When used with press ceramics, easy removal of the mold reduces the risk of ceramic chipping; the reduced stress also minimizes ceramic cracking. The investment powder comes in a 100-gram foil packet in boxes of 30 or 100 packets. The liquid comes in plastic bottles of 300mL or 2 liters.

The following patient’s restoration was created with One Shot HT Press over Pellets. When finishing a zirconia or metal substructure, pressing to the chosen substructure is very economical since most of the creation of the restoration does not need to rely on the skilled hands of a technician. Press pellets require a much smaller inventory, yet allow the laboratory to easily reproduce lifelike shade requirements. According to Shofu, Proven durability and beauty is provided with an efficient production method that doesn’t sacrifice esthetic results.

Starting with a casted metal framework, Saad will show us step by step how to create a bridge with just One Shot Uni-Layer HT Press Pellets and Ceravety Press and Cast Universal Investment.

Check out the following video to view the step-by-step case:

Continue to Page 2 to read about the procedure ...

Case study

1. We recommend finishing the metal framework with a Shofu diamond bur. This will help eliminate any debris that may be present, allowing smooth application of the base opaque. When alloy is ready, apply Vintage MP Opaquer Base with impeccable coverage so that none of the framework is visible except on the interior portions. This will give the final result a much warmer background Chroma.

2. Choose and apply the Vintage MP Opaquer paste according to your desired shade. Pay great attention to maximizing the coverage of the opaque application, just as before with the Opaquer Base. This is extremely important because the final color is determined by the opaque shade. If necessary after the first application, apply opaque once more and fire.

3. Before investment, full contour anatomic wax-up over the opaqued framework, do not over contour wax up. With One Shot Press, there is virtually no shrinkage of the final result.

4. Spru your restoration with shorter, thicker wax sprus than the traditional method (6-8 Gauge).

5. When your wax up is ready for spruing, DO NOT use any debubblizers. Spray wax pattern with distilled water and shake off the majority of the excess water. Do not let the wax-up completely dry, a small amount of moisture is recommended.

Bench mastery: Custom shade matching with an anterior implant case

6. Mix investment. We recommend starting with a liquid powder ratio of 10cc of investment liquid to 10cc of distilled water for each 100g envelope of powder. You can adjust the expansion by changing the ratio between liquid and water, but exactly 20cc total of a liquid/water combination is required. The more investment liquid versus distilled water that is added, the more expansion occurs in the final result.

7. Mixing bowl should be slightly wet before combining investment liquid and powder in the bowl. Mix investment under full vacuum for 1 minute, and pour inside of ring. Use minimal vibration. Bench set no more than 20 minutes. It is very important not to exceed 20 minutes for any size ring.

8. Remove investment ring from bases, clean up, and submerge in cold water for 5-7 seconds. Insert the wet ring inside of the burnout furnace at 1654°F (900° Celsius). Hold for one hour. For additional rings add 20 minutes hold time per ring.

9. Starting temp: 700° Celsius, heat rate 45° per minute, high temp 925°-935° (depending on your equipment) for 100g ring, hold for 20 minutes at the highest temperature (for 200g ring, hold time should be 30 minutes).

10. Once the ring is conditioned properly, the pressing can begin. With press application, it is important to NEVER preheat the ingot and plunger. We recommend using only disposable plungers which are available through most major dental supply companies.

11. Divest and finish with Dura-Green DIA and CoreMaster polishers. Stain and glaze with Vintage Art Stains.

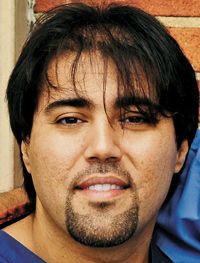

About the technician

Saad Elhallak MDC is a master dental ceramist. He received his master’s degree in dental ceramics at the UCLA Center for Esthetic Dentistry under Dr. Edward McLaren. Saad is the owner of Smart Solution Dental Lab in Huntington Beach, Calif. His lab specializes in high-end, all-ceramic esthetic restorations. In 2013, his lab started working with Shofu Dental, creating beautiful restorations out of their innovative materials. On his own time, Saad dedicates himself to experimenting with and testing different materials, talking dentistry and inventing new mixes for high-end laboratory products. He can be reached at ssdl7537@gmail.com.