Step-by-step: How the digital workflow makes global collaboration a reality

In this step-by-step technique for Dental Lab Products, Frankie Acosta explains how using the Sirona inLab CAD/CAM system has enabled his lab to do even international cases.

When I first started working with our Sirona inLab® System five years ago, I would have never imagined where it would take me and my laboratory today. We now work closely with CEREC doctors from around the world through the Sirona Connect digital platform, planning best treatment options and creating truly remarkable cases.

Same-day restorations have become a reality while working with “non-digital dentists,” as well as with CEREC doctors designing and scanning cases at their offices using chairside systems and then sending them to my laboratory to mill, and this process has worked in reverse also. Our lab has designed cases, and then we can send them back to CEREC doctors who are able to mill and finish the cases all while working chairside.

Related step-by-step: Using inLab for great results

Just recently, I’ve been given the chance to work simultaneously with a CEREC doctor on a full-mouth restorative case. The dentist started to design and mill a case from his office, sent me the file and then I continued to complete the case. Our lab was then able to deliver the finished restorations to the dentist’s office for an amazing same-day full-mouth renewal.

Throughout the years, many cases have really surprised me and have made me fully realize just how far digital dentistry has evolved and continues to change our profession. More recently, I have dabbled with some (as I like to call it) “international CERECing” as I’ve received more and more email inquiries from CEREC doctors around the world asking how we can work together. I turned down some of these requests solely because of not understanding the logistics of delivering cases to another country. In the past, I have attempted to deliver cases to Costa Rica, Mexico and Argentina yet had too many difficulties with transporting these cases in a reasonable amount of time and without damaging the restoration. For instance, one case I recently sent international actually made it to its destination, fully intact but took more than a month to get there.

News: Sirona announces new CEREC option and chairside furnace

Last month, I received a message from Dr. Daslav Ilic, a CEREC doctor located in Antofagasta, Chile. He had an issue where he wanted to copy a case chairside with his CEREC Omnicam. He sought to replace an existing bridge with full zirconia and pink porcelain but wasn’t able to locate a laboratory in his country that could process the scan. I told him to send me the scanned file so he could mill it with his own mill and then have a local laboratory add the pink porcelain. I’d like to share the case but it is currently a work in progress though it opened the door for the following “international CERECing” opportunity.

Case study

Fortunately, a case I can share with you is another one I worked on with Dr. Ilic. He helped me to efficiently and safely navigate the delivery process to Chile and then sent me a case via Sirona Connect for a full zirconia six-unit biocopy that he scanned with his CEREC Omnicam. All the way from Chile, I was able to partner with Dr. Ilic on a fantastic model-less case that I was able to create and mill using the new inLab SW 15 and the inLab MC X5 wet/dry milling unit, respectively.

Click the "next" button to go step by step ...

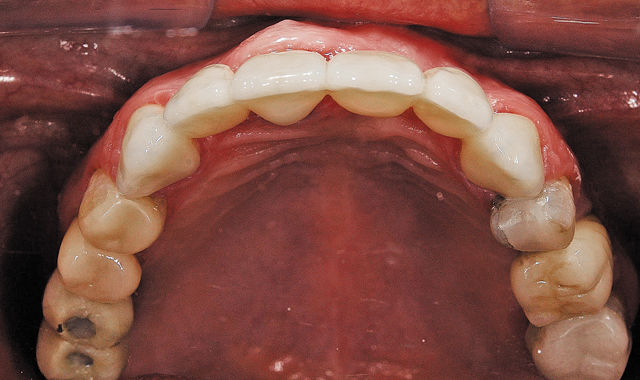

The patient's original smile.

The patient's original smile.

01 The doctor was presented with a patient who had a multitude of oral issues, including a collapsed bite, an underbite and several rotting teeth. The goal was to create an esthetically pleasing six-unit anterior bridge that would drastically change the patient’s appearance and lifestyle (Fig. 1).

Four-unit anterior bridge design.

Four-unit anterior bridge design.

02 The doctor first created a four-unit anterior bridge chairside for the patient to establish an initial bite (Fig. 2).

Crownwork in the posterior region.

Crownwork in the posterior region.

03 The doctor then added some crownwork to the posterior region to raise the bite. As you can see from the image, this instantly made a major improvement to the overall appearance of the mouth. With this particular alteration, the patient was now on his/her way to having a normal, functional bite and a more esthetically pleasing smile (Fig. 3).

Provided mouthguard.

Provided mouthguard.

04 As a protective measure, the doctor provided the patient with a mouthguard to protect his temporary work while awaiting the completed and final restorations from our laboratory (Fig. 4).

Six units temporary bridge and mandibular partial.

Six units temporary bridge and mandibular partial.

05 The doctor then fabricated temporary removable partials for the patient, and now the patient’s new bite was 100 percent established and ready to be created and transformed into reality (Fig. 5).

The doctor was able to scan the case chairside using the CEREC Omnicam and then sent the scan to my laboratory digitally via the Sirona Connect network. With inLab’s new Software 15 (SW 15), I can now utilize the amazing new biocopy function to perfectly design and replicate the temporary and then send the six-unit case to mill on the inLab MC X5 wet/dry milling unit.

Fig. 6 Maxilar bucal view from final bridge from Connect Case

Fig. 6 Maxilar bucal view from final bridge from Connect Case

Fig. 7 Oclusal view from provisional bridge, chairside made

Fig. 7 Oclusal view from provisional bridge, chairside made

Fig. 8 Bucal view CO: Final bridge from Connect Case

Fig. 8 Bucal view CO: Final bridge from Connect Case

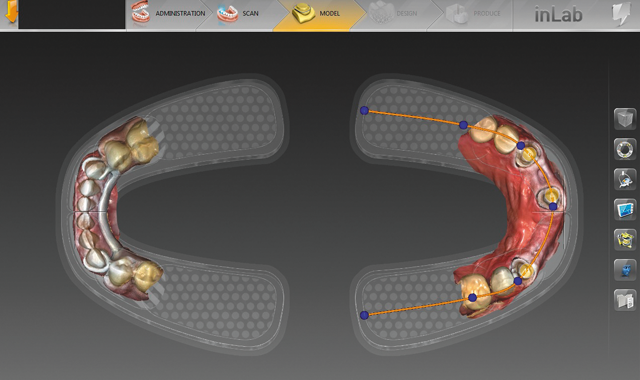

"Set model axis" function

06 Once I downloaded the scan, I was able to place the image in the full-model arch and align the model in the “set model axis” function, which also provides me with a virtual articulator view. I was able to perfectly align the teeth midline, as well as the entire case, according to the biocopy of the temporaries (Fig. 9).

"Edit jaw line"

07 Now I am able to align the tooth numbers to the preps by using the “edit jaw line” function. This function maps out the tooth numbers to provide a clear outline of exactly where the teeth are to be placed for ideal fit and function (Fig. 10).

"Define insertion axis" function

08 Because we’re using the MC X5 to mill, I now use the “define insertion axis” function to articulate precisely how each tooth number will be inserted within the parameters of the case (Fig. 11).

Morphology tool

Morphology tool

09 Another unique feature of the new inLab SW 15 is the morphology tool. In this tool, I can choose from a list of tooth shapes, the biogeneric method that analyzes the patient‘s intact tooth surface as a basis for computing the occlusal morphology or the tooth database, which provides different dental databases of teeth from leading manufacturers, such as VITA (Fig. 12).

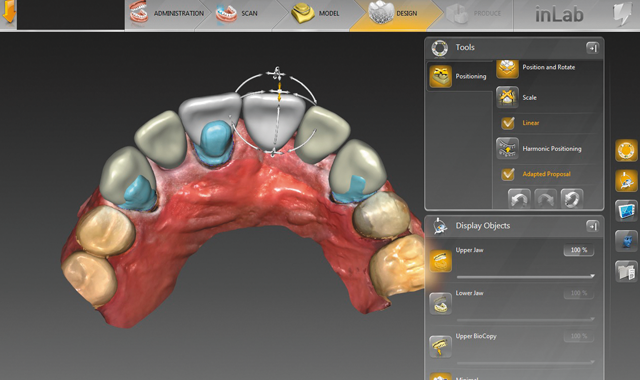

Biojaw function

Biojaw function

10 The biojaw function, located in the “positioning” tool, aligns and places all the teeth as I control each and every move for the most favorable positioning. The software will do whatever or wherever I place it, an unprecedented function where I can now actually guide the software (Fig. 13).

We have the options of harmonic positioning, which will best position the teeth according to the surrounding area, or the linear option, which will align the teeth according to exactly where I navigate and place them.

Case proposal

Case proposal

11 Once everything is aligned, I can create a six-unit case in less than a minute. This is the proposal of the actual case. This is an important feature because once it’s placed, the software automatically finishes it up but the user also has the option of making any necessary adjustments (Fig. 14).

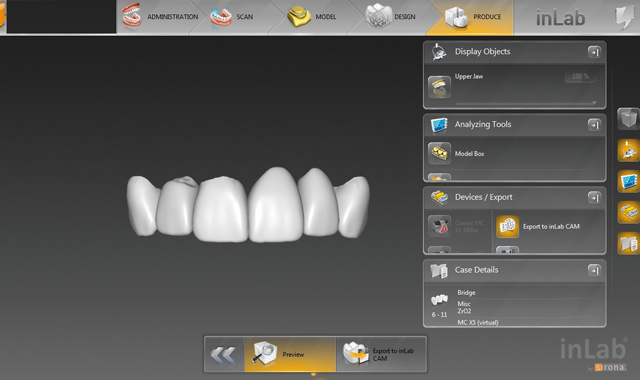

Finished case

Finished case

12 Now we have a display of the actual finished case. I can now simply export the file to the inLab MC X5 wet/dry milling unit, and it’s ready for milling. The final product was milled with zirconia and then shipped it back to Chile. Both patient and doctor were extremely pleased with the results (Fig. 15).

Conclusion

After processing and completing this case, I realized my Sirona journey has taken me to levels in my industry that I would have never imagined. Sirona’s inLab division has sent me all over the United States to work side by side with CEREC doctors from all walks of life. Now that Sirona has opened up the international door, I will now further explore to see how far it will take me and my laboratory.