How digital dentistry and 3D printing are changing dentures

With more patients seeking out digital dental technology, digital dentures may soon become the norm.

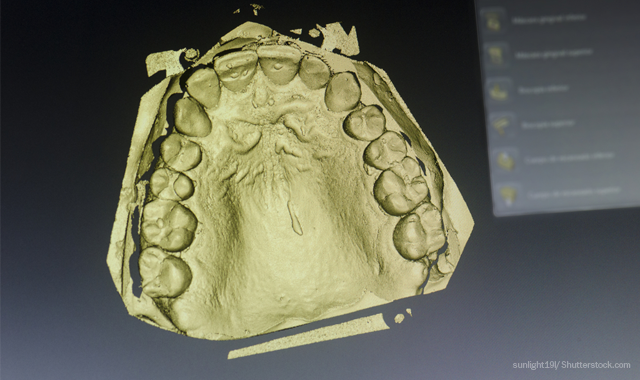

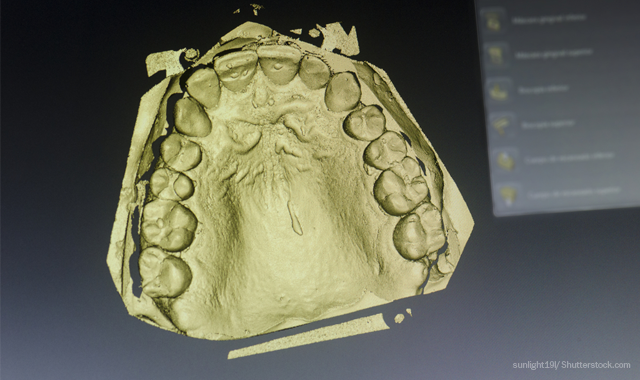

Ask any expert in the dental industry about digital workflow and the manufacturing of restorations and he or she will likely tell you how fantastic it is for crowns, bridges and implants, among other things. However, he or she probably will not mention the excellent performance for dentures or removable partial dentures. Why? Because up until recently the technology couldn’t handle it.

Dan Elfring, CDT and in-house technician at Pickle Prosthodontics, has been a technician for 40 years and making dentures for more than a decade. He says dentures are the “laggard specialty” in digital dentistry because of challenges in scanning soft tissue and moveable attachments and printing or milling around those soft tissue movements involved in dentures.

“Most of the scanners would only scan a static object, but as your mouth moves, your tissue moves, and the functional position wouldn’t be captured. This discrepancy would cause ill-fitting dentures,” Elfring says. “But that has been changing rapidly in the last one to three years even. They are getting some very good results with digital dentures now."

Josh Gall, general manager of Axi Dental Lab, agrees that while technology is improving rapidly in the area of scanning soft tissue, many dental professionals are still skeptical about making dentures from an end-to-end digital process. In digital fixed dentistry, the technology excels at capturing the detail necessary for a restoration when scanning hard tissue. The challenge is capturing an accurate scan of soft, malleable tissue like gingiva or the palette. Dental labs often get scans with distortions where the hard and soft tissue meet or scans where the camera didn’t get the area at all.

“So if scanners had trouble accurately capturing just a little bit of soft tissue in that small area around a crown preparation, how are we going to rely on that accuracy with an entire scan of an edentulous mouth that has no teeth in it and trust that we will be able to make a denture that will fit comfortably?” Gall asks.

Gall says that most dentures are still made from a physical model at the lab, whether the impression was taken digitally or traditionally. Since working in the patient’s mouth is impossible, a physical model of it is the next best thing. However, he says he thinks that going fully digital with no physical model is a possibility based on improvements in the scanning technology.

“From what I have seen lately compared to a year or two ago, that accuracy is absolutely improved and this could very well become an entirely digital process,” Gall says.

Justin Marks, CDT, has 15 years in the dental lab industry and a background in dentures and partials. Marks is passionate about digitizing the dental lab, particularly those that use traditional techniques that can be time-consuming and wasteful. He founded his company, Arfona, on the philosophy that 3D printing of dentures and partials should be more accessible and not as expensive as it is now.

“The design software that is available allowed us to design dentures and partials digitally, but printing hadn’t really caught up with it yet,” Marks says. “We were in the position where it looks great on the screen after you designed it, but how do you turn that into a tangible object for delivery to a patient?”

Dental laboratories used many materials to fabricate dentures and partials, but a digital manufacturing process didn’t exist. Marks worked with a materials manufacturer to develop a method for 3D printing using their materials. Per Marks, there are many advantages to employing a digital workflow for full and partial dentures, including:

- Facilitating faster and more collaborative communication between technician and prescribing dentist

- Increasing precision with the digital design and reducing finishing and fitting efforts once processed

- Improving esthetics and occlusion as a result of customization opportunities for replacement teeth

- Streamlining tooth arrangement and grinding needed for contacts and occlusion

- Reducing the denture fabrication time by eliminating the model duplication, hand-waxing, flashing, boil out and injection molding steps used in traditional fabrication processes

- Decreasing material costs resulting from streamlined processes that no longer necessitate grinding or residual losses of material in the milling blank.

Marks says that clinicians who use intraoral scanning could not only speed up the pace in which dentures are fabricated but also reduce the number of appointments that are needed to deliver a final restoration.

“For example, it’s still experimental for full dentures, but for partial dentures it used to take two or three appointments just to capture the final impression and the bite registration. That can be done through a single appointment using intraoral scans,” Marks says.

The Journal of Prosthodontic Research published a case report last year that details how an intraoral scanner can get the necessary detail needed for a digital denture fabrication workfow.1 Using a scan retractor, the clinician was able to retract the lip, cheek and vestibule tissue effectively on a 60-year-old man’s maxillary complete denture. The interocclusal record was also scanned, providing a digital vertical dimension on which to build the denture base and teeth. Then the team was able to create a customized denture that optimized the patient’s occlusion through an entirely digital workflow.

Elfring doesn’t fabricate his dentures digitally, although his in-house laboratory is investigating options that would work for their production volume. However, as an outsider looking in, he sees that there are numerous advantages to producing dentures digitally. The digital file is a significant advantage because you can always scan or build a new denture when they it breaks or wears over time.

“If a patient is in a nursing home and they lose a denture, which is very common, it’s easy to print or mill a new one because you always have a digital file,” Elfring explains. “If you want changes, you just swap out the different shade of teeth, or as they age and you want to go one shade darker, it’s easy to do. Conventionally, it’s more time-consuming. You are back to the typical three to five appointments.”

Elfring sees other advantages to a digital workflow. For example, shifting a midline would be easier to do digitally. Conventionally, Elfring says he has to move each tooth and rotate it or change the occlusal plane, but with digital you adjust it on the screen. Elfring also likes how you have access to a tooth library, so you don’t have to maintain a large tooth stock inventory.

That said, Elfring loves producing the dentures and working with patients to make them fit.

“I work directly with the patients and make adjustments of the try-ins. I am working hand in hand with the patient designing their new smile. There is a lot of job satisfaction in that for me,” he says.

Gall also doesn’t have experience producing digital dentures yet but recognizes it would have some advantages over conventional fabrication, especially for predictability. Dentists, patients and technicians have a chance to see and make adjustments to the dentures before they’re even made. Conventional fabrication has a lot of trial and error associated with it from choosing a mold shape to tooth size to color and any number of other details.

“You have the denture on the screen in color and now you have the option to pick a mold of the tooth virtually that fits the patient. So if they want the teeth longer, more rounded, more squared or any other detail of the anatomy, all of those things are a couple of clicks away with a mouse,” Gall explains. “You can make huge changes easily in comparison to going through a shade and mold guide and guessing, then having multiple set-up try-ins and multiple office visits.”

Gall says digital fabrication also gives the technician more control over the details, like the thickness of the denture base.

“You have the exact measurements as opposed to just flowing some wax and trusting the acrylic will process accurately,” Gall says. “If I want the middle of that denture base to be 2 mm thick, it’s going to be 2 mm thick because I told it to be when I designed it.”

CAD/CAM technology has had a few decades of development at this point. Marks believes clinicians and technicians should reconsider how digital equipment can help design and fabricate both removable partial dentures as well as full denture appliances not only for all these benefits but also because patients want it.

“They, the patients, are looking for digital technology. They expect it,” Marks says.

References

1. Fang, J H, et al. “Development of Complete Dentures Based on Digital Intraoral Impressions-Case Report.” Www.ncbi.nlm.nih.gov, PubMed, 16 June 2017, www.ncbi.nlm.nih.gov/pubmed/28625663.