A guide to selecting digital dental materials

There are a lot of choices for digital dental materials. Strength, esthetics, inventory management, and workflow must all be considered before picking the right material.

Once the decision to incorporate a digital workflow into the practice is made, there are no shortage of options of digital dental materials to choose from. However, choosing which one to use and why depends on the case being treated and the technology being used.

Below are some ways to easily make the transition to digital materials.

Match the digital material with the workflow

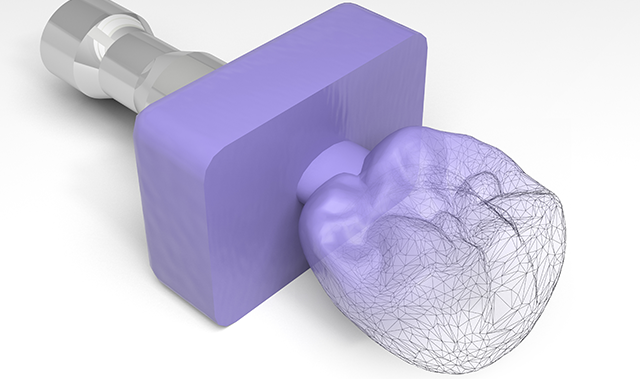

Nathaniel Lawson, DMD, Ph.D., an assistant professor and director of the Division of Biomaterials at the University of Alabama at Birmingham School of Dentistry, says dentists performing in-office milling with CAD/CAM dentistry are limited to using restorative materials that are available in the blocks that fit into their milling machines. Additionally, they are limited to using blocks that have mandrels which connect to their specific milling machine.

“For some materials, such as zirconia, they may require a specific furnace to sinter their restoration once it has been milled,” Dr. Lawson says. “That being said, there are many restorative materials available in block form to be milled in-office.”

No choosing between esthetics and strength

John Flucke, DDS, and Technology Editor for Dental Products Report looks for two things in any dental material, digital or otherwise-esthetics and strength-on a case-by-case basis.

In the past, lithium disilicate was the material of choice and everybody loved it, Dr. Flucke says, but it would occasionally break. Zirconia offered strength, but it didn’t look very good in the esthetic zone. Dentistry has been lucky in the past five years to get esthetic zirconia materials that provide strength and improved esthetics, according to Dr. Flucke. Between improved shade matching and the appearance of translucency, he says esthetic zirconia products allow clinicians more leeway about the type of materials they use and where it’s used, in some cases.

“They still are not as esthetic as lithium disilicate, but you can get away with putting them more in the esthetic zone,” Dr. Flucke says. “That’s been really nice. I don’t have to choose between going strong or going beautiful. Sometimes you still do have to make that choice but fortunately, that’s a lot rarer than it used to be.”

Make it easy

Strength and esthetics are two crucial characteristics that digital dental materials need to have, and that both of these characteristics exist amongst digital materials today, agrees Chad C. Duplantis, DDS, FAGD. The third characteristic is that they must be user-friendly, especially for chairside, he says.

“When choosing chairside materials, the clinician must answer two simple questions. First, ‘Can I do as good of a job as the laboratory?’ The second question should be, ‘Can I do so in an efficient manner?’” Dr. Duplantis explains.

Design for either pucks or blocks

One difference in comparing CAD/CAM materials is whether it comes in a puck or a block. This specific detail will affect how the restoration is designed. For example, when the crown is created from a puck, be aware of the puck’s design, too, Dr. Flucke cautions.

“You've got to watch out, because if you're not careful, you can end up where the machine thinks it's cutting something when there's already a hole in the puck,” Dr. Flucke says.

Assess the surrounding dentition

There are a few things that need to be considered when choosing a material, Dr. Duplantis says. First, the surroundings of the current dentition should be assessed.

“If there are several lab fabricated crowns made of non-digitally available materials, you are best off sending it to the lab,” Dr. Duplantis says.

Also, assess the shade of the teeth in the vicinity of the restoration, he adds. Will the restoration require characterization or translucency? If so, will there be the appropriate material to match the adjacent material, and/or is there the ability to characterize the restoration to match the adjacent dentition?

“When assessing the adjacent dentition, you must also assess the wear which can lead you to decide upon the strength requirements of the new restoration,” Dr. Duplantis says. “In a patient that has serious wear or an excessive bite force, you’ll want to use a strong material such as zirconia. If you use a glass ceramic, the strength of the material may lead the restoration to be more prone to fracture. This is especially true for full coverage restorations,” he says.

Dr. Duplantis’ practice uses full strength zirconia (3Y) mainly in the molar region for full coverage restorations, and rarely on the second bicuspids. The bicuspid and anterior region is case-dependent, and they can use an esthetic (5Y or 4Y) zirconia. All inlays and onlays are treated with a hybrid ceramic.

“On inlays and onlays, my go-to material is a hybrid ceramic,” Dr. Duplantis says. “These materials are particles of glass ceramic or zirconia in a resin matrix. The strength of these materials is much less than we would usually be accustomed to, but this allows wear in a manner consistent to the tooth. Additionally, these materials are esthetic and wear-friendly to the opposing dentition as well.”

Consider a different approach to inventory

When first moving into digital dentistry, you may think it’s necessary to stock all of the shades. However, if the shut down during the COVID-19 pandemic has taught dentists anything, Dr. Flucke says, it is to reconsider how to handle the inventory.

“You may have gone in to handle an emergency by yourself and had to look through a couple of things. And I know I've looked and opened up a drawer or something and gone, ‘When did I get this? I haven't seen that in five years! I totally forgot I even owned this,’” Dr. Flucke says.

From an inventory standpoint, Dr. Flucke suggests considering whether it’s a requirement to have all of the different shades of material in inventory. If you buy all the shades for your inventory, you might only use a couple and the rest will collect dust in the inventory closet. While these permanent prosthetic materials will not expire or “go bad” over time like some other materials can, all those blocks of less common shades can be a lot of overhead cost to absorb.

An alternative is to determine what shades are used the most and only stock those. For example, Dr. Flucke says that the most common shade he uses is A2, so he ordered four shades in his initial setup, A2, A3, A3.5, and B1.

"I didn’t order every shade that was available because the majority of them do fall into that A2 range,” Dr. Flucke explains.

Additionally, there’s no hard and fast rule that all indirect restorations be done in-house or even in every shade once you invest in digital workflows. Dr. Flucke says that once you take the digital impression, and it’s all “ones or zeros,” you can keep the production in the office, or it can sent to a lab.

“If you want to do the majority of things in-house and you don’t really want to have all the inventory, then, just do in-house restorations for patients that fall in that shade range,” Dr. Flucke says. “And then if it’s something that’s way off the scale, have the lab do it.”

If you still want to handle everything in-house, you might try more of an “on-demand” inventory process. Dr. Flucke suggests noting the shade in the patient record when you go over the treatment plan at the patient’s hygiene appointment. Then, when the patient is ready to move forward with their treatment, you can order the digital material in the proper shade before the appointment.

“Just make sure that they are scheduled out far enough that you can order in a box,” Dr. Flucke says.

On the other hand, Dr. Duplantis recommends starting with a diverse stock of materials. His practice has three categories of materials-glass ceramics, hybrid ceramics, and zirconia. He says they use the zirconia and hybrid ceramics the most. They have all of the shades available in these materials and replenish as they get down to fewer than four blocks of one material. Additionally, all of their digital materials and accessory armamentarium is located in close proximity to the mill, making it easier for them to manage inventory.

“We have a cabinet that we keep all of the materials in on the wall next to our mill. We keep an eye on the count as we pull a certain material and make sure that we have at least four left at all times. Inventory is hard to manage getting started in chairside dentistry, but after a few months, it is very easy to realize what you use the most of,” Dr. Duplantis says.

Work with what works best for you

Prep design is the most important element to prevent problems with a restoration, Dr. Duplantis says. Understanding the prep design of the tooth is imperative.

“Most failures that I have seen are due to inadequate reduction,” Dr. Duplantis says.

He also recommends knowing the characteristics of the materials that are used. Then, after some time, dentists will find what they like best band what works best in the practice, Dr. Duplantis says.

“If you succeed with a material that works for you, and it is used according to manufacturer’s recommendations, then that’s fine,” Dr. Duplantis says. “There are many options available. Do your homework, research the materials, and take some time to learn how to properly use them.”