Glidewell’s New Enhanced Implant Scan Bodies Designed to Streamline Digital Workflows

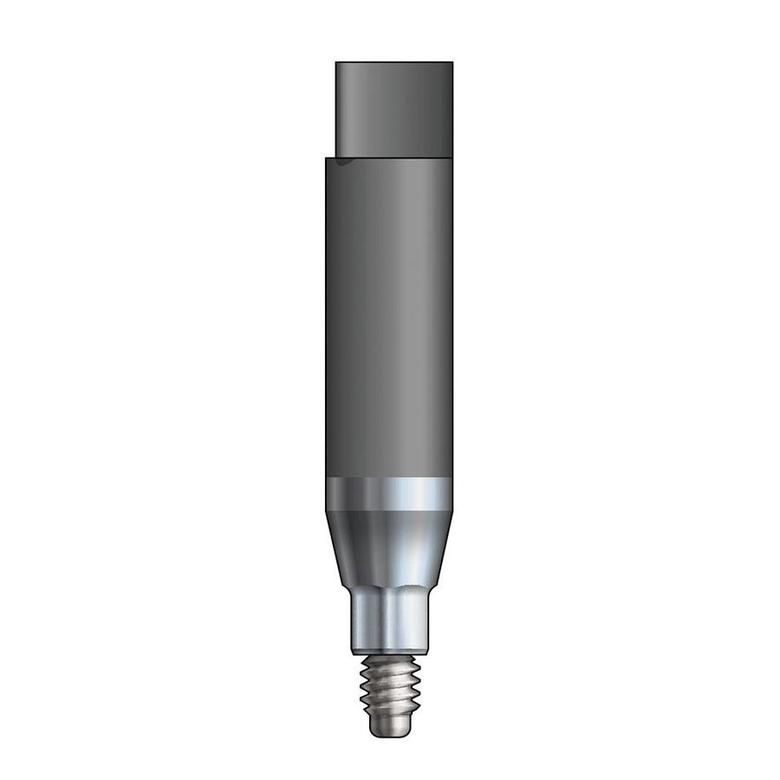

Fabricated from medical-grade titanium, the newly designed scan bodies offer customers a solution that saves time and streamlines their work flows.

Glidewell just released newly designed scan bodies to simplify the digital impression process for implant restorations. The new Hahn™ Tapered Implant Titanium Scan Body and the Inclusive® Titanium Scan Body, which is available for most major implant systems, are produced from medical-grade titanium with features designed to streamline the restorative process.

Suitable for use in both the anterior and posterior, the new scan bodies feature a microtextured surface that does not require powder or sprays. They are also durable and can be sterilized, and their proprietary geometry is designed to enhance the accuracy of occlusal registrations.

For 50 years, Glidewell has been known for its dedication to advancing dental technology to deliver better results for dentists and patients. Now, Glidewell has taken the next step by transforming the digital scanning process used in restorative implant dentistry. According to Grant Bullis, vice president and general manager of manufacturing at Glidewell, these new titanium scan bodies make things simpler, more convenient and more affordable through the design and manufacturing of components that streamline implant technology. He adds that they will save labs and clinicians time and money while facilitating a better image acquisition from the onset.

The Inclusive Titanium Scan Body is currently available for ASTRA TECH Implant System®, BIOMET 3iTM Certain®, Hiossen® HG System, MegaGen AnyRidge®, Nobel Biocare NobelActive®, Nobel Biocare NobelReplace®, and Zimmer Dental Screw-Vent®. New scan bodies will be available for additional implant systems later this year, according to Glidewell Dental.

To learn more, visit glidewelldirect.com or call 888-303-3975.

Editor’s Note: Hahn Tapered Implant is a trademark of Prismatik Dentalcraft, Inc. All third-party trademarks are property of their respective owners.