Building a digital workflow one step at a time

How to know when to add various technologies to your office from scanners to mills to 3D printers.

If you’re ready to incorporate digital dentistry into your practice, you’re probably wondering how to get started. What do you need to buy first, and which technologies do you add from there?

It can all seem a bit daunting, but with the right guidance, you can seamlessly integrate technologies such as scanners, mills, 3D printers and CBCT units into your workflow-making your practice more efficient and enabling you to offer additional services to your patients.

“By digitizing, you streamline your practice and make dentistry more predictable,” says Dr. Chad Duplantis of Fossil Creek Dental Partners. “Every clinician who wants to improve the quality of the work they’re producing should look into going digital.”

Despite what many dental professionals might think, making the move to a digital workflow doesn’t have to cost upwards of $100,000 all at once whether you’re a dental practice or a lab, says Lee Culp, CDT, of Sculpture Studios. As demand increases, costs associated with these technologies are coming down, making it easier to invest in them and to start reaping the many benefits they provide.

Related reading: How digital workflow is affecting laboratory artistry

Start with a scanner

The first technology you need to invest in if you want to build a digital workflow is a scanner, Dr. Duplantis says. While you can purchase a mill at the same time, it isn’t necessary. Dentists used to have to buy the mill and scanner at once, with the scanner only really able to mill restorations. That’s not the case anymore. Today’s scanners have endless capabilities. They provide a great introduction into the world of digital dentistry and allow you time to adjust to a new workflow before you take the next step.

Dr. John Flucke, chief development officer for Cellerant Consulting and chief dental editor and technology editor for Dental Products Report agrees, and he suggests first investing in a scanner that’s upgradeable. For example, you might purchase a scanner with a black-and-white screen because it’s less expensive, knowing you can upgrade to a color screen and other features such as a wireless wand when you have the cash flow to do so.

Starting with just a scanner also means you can basically continue to do things the way you used to, Dr. Flucke says. You can still send cases to the lab to make your crowns, bridges and dentures. You just have a more efficient, accurate way to get them the information they need. So, while the new technology impacts your workflow a little, it isn’t an overwhelming change for you and your team members.

“I’m big on eating the elephant one bite at a time,” Dr. Flucke says. “Sometimes people get really excited and just want to jump in. They add five steps at once, when in reality, it’s much easier to start at step one, get really good at step one and then add step two. It’s also better for your bank account from the cost benefit standpoint.”

What about software? You’ll want to get the software you’re going to use when you purchase the scanner, Culp says. Most companies are bundling software with the scanners, but it’s important for dentists and labs to make sure they’re getting intuitive software they’re comfortable using.

Continue reading on page two...

Next up, the mill

For dentists who want to offer their patients same-day dentistry, their next purchase should be a mill, Dr. Duplantis says. Just keep in mind a mill is essentially an accessory you may or may not want. Make sure you’ll actually use it before you make the investment.

When determining the best mill for your practice, look for a system that’s cost-effective for the type of restorations you want to produce, Dr. Duplantis says. If you’re only going to use it for single restorations, for example, decide if it’s really worth the cost. Buying a mill shouldn’t adversely affect the way you practice dentistry, and the restorations it produces should be the same quality you’d get from your lab.

More from the author: Taking composite materials to the next level

While adoption of mills in dental offices is growing, it’s not as fast as scanners, Dr. Duplantis says. Many dentists are buying scanners first, and then they may or may not buy a mill down the road. You just need to decide what works best for your practice.

For labs, Culp suggest outsourcing restorations to groups to do the milling for you to start. When outsourcing costs the same as it would to purchase a mill, then it’s time to consider making the investment.

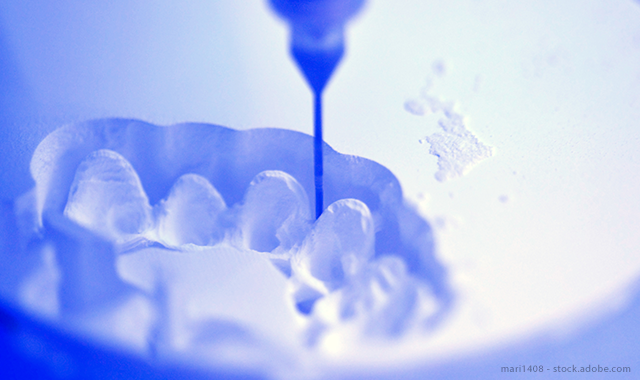

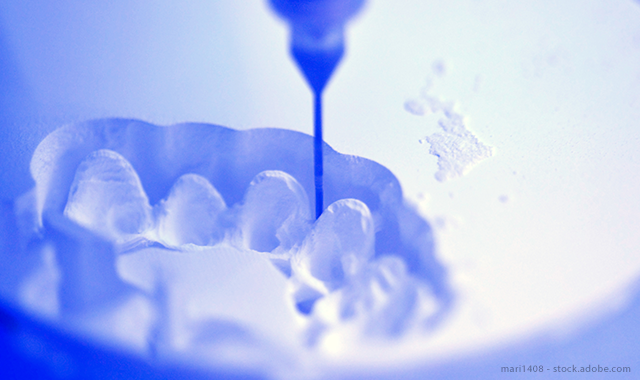

Do you need a 3D printer?

It depends on what you want to do. While printers are a hot topic right now, you have to figure out if the cost is truly worth it. Before making the purchase, determine if you’ll be able to use it to its full capacity and eventually make money on the purchase. Some dentists may never get to the point where they need a 3D printer, and that’s OK.

If you’re really only interested in offering same-day restorations to your patients, a mill is your best bet for now, Dr. Flucke says. While there are companies working on it, printers can’t yet produce restorations that go straight into the mouth. So, mills have capabilities printers don’t, and you may not need both, depending on your goals.

“You have to decide if you want it because it’s cool and because patients will perceive your practice as cutting-edge, or if you’ll actually integrate it into your practice and use the capabilities,” Dr. Duplantis says. “If you’re paying on it just for it to collect dust, then it’s worthless to you.”

Ask yourself how you want to use the printer and what capabilities you’ll need, Dr. Duplantis says. Typically, dentists use 3D printers for orthodontic aligners as well as for fabricating temporaries, surgical guides, splints, night guards, models and dentures.

Trending article: The virtues of beautiful design

“Implants are a huge reason for growth in 3D printers. From an efficiency and safety standpoint, it’s better for implant surgery to have the guides 3D printers can provide,” Dr. Duplantis says. “And a lot of dentists want to print their own clear aligners and retainers so that they can have more control over the ortho treatment workflow than if a company handled the fabrication.”

Once you determine what you want to print, it’s also important to think about size, Dr. Flucke says. Some printers may only be able to print at 1 cm by 1 cm, which may be too small to fit your needs, for example. Bottom line: know what you want to do with the printer and make sure it has those capabilities before making the investment.

If you decide you do want to add a printer to your practice, Dr. Flucke suggests going with a company with stability. Because this is a rapidly growing market, there are a lot of new players who may not be around in a few years. Find a company with a solid reputation. You don’t want to buy a product that you won’t be able to get support for because the company went under.

It’s also important to consider print speed, cost, the size of the platform, and available colors and resins when deciding which printer to buy.

Continue reading on page three...

Cone beam

Like the 3D printer, this is another technology that’s user dependent, Dr. Duplantis says. Cone beam technology is a must if you place implants, and it might be worth adding a printer for surgical guides as well. But if you don’t place implants in your practice, you may be able to go without cone beam for now.

“The printer and the cone beam come after the scanner and the mill because the digital workflows grow on each other by adding capabilities,” Dr. Duplantis says. “Some dentists may never get to a cone beam or 3D printer.”

If you do incorporate cone beam technology into your practice, Dr. Duplantis suggests working with a radiologist who knows how to read the scans. A radiologist may see something you don’t, which could alter disease progression if treated properly.

Related reading: How to use a 3D digital workflow for ortho treatment

Is it time to begin your digital journey?

If you’re ready to improve the quality of the dentistry you provide as well as enhance practice efficiencies, the answer is yes. You’ll save time and money while also providing your patients with exceptional care.

The technologies continue to improve, and now practices and labs must make the cultural shift, Culp says, and start thinking with a digital mindset. It’s important for dental professionals to be committed to the idea of going digital and to understand the benefits it brings to everyone, including the patient.

To be successful, it comes down to taking it slow and purchasing the technologies that have the features and capabilities you want, Dr. Duplantis says. Make sure you’re ready before moving on from one technology to the next. There’s no magic amount of time you need to spend mastering your new scanner before you invest in a mill. Get comfortable with the scanner at your own pace, and then add the next technology.

“Some doctors might be ready to take the plunge all at once, but adding the technologies incrementally allows you time to get through the learning curves to see what other needs you may have in your practice,” Dr. Duplantis says. “Every one of these systems comes with a new set of software, so there’s a learning curve associated with them. The time it takes to move from one step to the next is user dependent.”