Behind the Scenes: Worthy of the spotlight

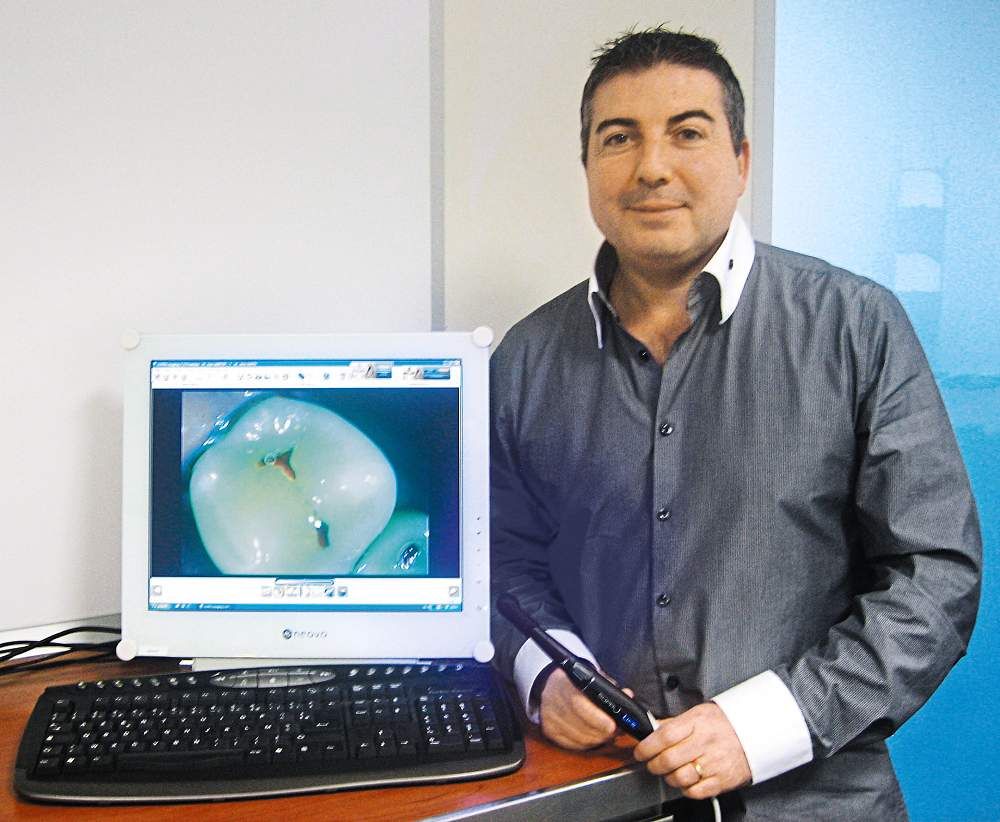

Gendex Dental Systems Filippo Impieri, Global Product Manager 8 years with the company, worked on the GXS-700™ digital sensor

Gendex Dental SystemsFilippo Impieri, Global Product Manager8 years with the company, worked on the GXS-700™ digital sensor

From the time an idea begins to take shape until the day the product is launched, Filippo Impieri is there. He gets to help transform the initial idea into something dentists will use to provide their patients with better care, what he describes as a position he’s privileged to be in. As the product manager responsible for the digital sensor and intraoral x-ray business at Gendex, he spent a lot of time and effort getting the GXS-700 digital sensor to market.

Product development is an exhilarating process, he said, but nothing beats that last stage. Bringing the product to market and watching how it benefits the industry, that’s truly the most rewarding part of his job.

“There’s really nothing better than that. Seeing the reaction of clinicians across the world to this sensor has been a terrific experience,” he said. “Bringing a product to market and seeing how it makes a difference in the daily lives of thousands of practitioners around the world is the best part of product development. I think it’s just priceless.”

Plans for the GXS-700 began right after Gendex’s previous generation of the sensor was released. From the market research findings, Impieri said the team decided it was best to focus on image quality, improving diagnostic ability, portability and patient comfort. And that team is a large one made up of individuals with different specialties, something Impieri said is critical to a new product’s success.

“We have to make sure no aspect of the product is neglected during the development phases. We focus on things that matter the most,” he said. “It is truly a cross functional and global effort. In the case of Gendex, we have resources and contributors from across the country and overseas. All parts of the organization were involved from marketing to engineering. There’s no department in the company that was left out. It truly is the result of the hard work of every single Gendex employee.”

Carestream DentalWes Newsom, Product Line Manager8 years with the company, worked on the Kodak 1500 intraoral camera

It’s all about giving you what you want.

As a product line manager for the Kodak 1500 intraoral camera, that is Wes Newsom’s top priority-to find out what you need to have in an intraoral camera and to make it happen.

What’s one of the best ways to do that? To actually watch dentists use their intraoral camera of choice in their practice, Newsom said.

“We stand in the shadows and watch how they do things. We look at what is clumsy and what frustrates them in the workflow,” Newsom said. “We see people with older generation and competitor cameras and find out what they like and what they don’t like about the cameras. We watch the workflow without interrupting, and that seems to give us good information on how to make the product better.”

When working on a product like the Kodak 1500 camera, Newsom visits between 10 to 20 offices, with most having one or two dentists and five to seven staff members to observe and talk with them about what they need in an intraoral camera to provide their patients with the best care possible. But that’s not the only feedback Newsom and the rest of the product team use in the development process. They talk with key opinion leaders, set up focus groups and involve a variety of people throughout the company, from sales support to engineers, to get their opinions on how to improve the product. All told, there are hundreds of people from inside and outside the company who have a hand in creating and updating products at Carestream Dental.

And it doesn’t end after the product is released. This intraoral camera originally was released with a docking station. Now it has wireless and direct-to-USB versions to help make the product even more user friendly.

“Once we actually have the final product working like we wanted it to work, we get it out to larger quantities of dentists and get feedback,” Newsom said. “They say it’d be nice to have this or that, and we work as quickly as we can to get those features put in. We do what we can to make the product fit their needs as quickly as we can and to make sure it’s really the right feature to put into the product.”

Discus DentalPhillip Pasit, Global Product Manager of Clinical Dentistry

15 months with the company, worked on Nuance

Tell me about your involvement with Nuance. What was your role in its development?

As you may already know, the composite market has many different players. As Discus prepared to introduce its new composite, we wanted to showcase not only a composite that delivers exceptional esthetic results, but a unique delivery system that is innovative and functional for the user. With any development process, it’s important to acquire Voice-of-the-Customer feedback. This research ensures your feature sets offer true benefits to your audience. I reached out to several Luminaries, well-known for restorative dentistry, to confirm value in our delivery system, and seek a positive response on our nano-hybrid universal composite. In turn, Voice-of-the-Customer research allowed me to develop a solid positioning statement and meaningful messaging that addresses true pain points to the target audience.

What all goes into the development of a product like this?

Product Managers are the hub in a new product development cycle. We are in charge of managing not only the product, but also providing guidance to the other stakeholders involved in making Nuance a successful launch. Teamwork with cross-functional departments is essential, and it’s my goal to make sure everyone is singing the same tune in unison. There are many moving parts in a product launch, from designing and engineering, filing regulatory requirements, manufacturing, and quality control, to developing marketing material and communications, advertising, and enabling our sales reps to be solution providers. Teamwork is key, and Nuance was humming on all cylinders when it was released in the marketplace.

What do you think dentists would be most surprised to learn about the behind the scenes of product development?

How much impact their voice has in the product development cycle. As manufacturers strive to develop products that differentiate the company from the competition, it’s very easy to get carried away with too many “bells and whistles.” As with many other products (not only in dental) customers frequently ask, “Why did they add that feature, I’m never going to use it?” As Discus develops products, we want to integrate features that are meaningful to our customers. Clinicians may not know there are impromptu market research focus groups that Discus holds. Qualified clinicians can be part of this study, to have their voice heard and further impact the development of dentistry.

Garrison DentalStacey R. Buckner, Export Sales Manager

13 years with the company, worked on the BlueView line of transparent matrices

Stacey Buckner typically is the one selling the products Garrison Dental launches.

This time, she was the driving force behind a product’s development. From coordinating pre-market evaluations with dentists to making sure they had everything needed in house to manufacture the product, she was involved in just about every aspect of the BlueView cervical matrix system’s development. And it all happened because her boss asked her to take a phone call. That phone call led to others, and eventually Buckner was immersed in a different side of the business, something that gave her an even deeper appreciation for the products she sells.

She loved being part of all the different pieces that go into product development. In particular Buckner enjoyed helping the company capitalize on its leadership position in Class II sectional matrix materials and expand into new innovative materials for Class III, IV and Vs. Her extensive pre-market testing of all the BlueView products gave her confidence that they would fulfill that goal. So far they have, she said.

And when it comes to product development, Garrison is always open to new ideas to expand the company’s offerings, Buckner said, whether those ideas come from within the company or are from the dental community.

KaVoAmod Kher, Senior Product Manager

3 years with the company, worked on the MultiLED

Amod Kher is a problem solver.

That’s how this senior product manager sees product development-you identify a need in the market and you develop a product to fill that need. So what need does the MultiLED fill? It upgrades the ubiquitous six-pin MULTIflex coupler from a halogen bulb to an LED without buying a brand-new LED coupler. The market needed a clean white light in the oral cavity for dental applications, Kher said, which is what this upgrade provides-at a price that’s affordable for existing users of the MULTIflex couplers who want to upgrade.

Kher and the others on the development team spent about 14 months on this product from start to finish, Kher said. During that time the focus was on innovation, and taking an existing successful product and making it even more user friendly.

“The whole process from the ideation to commercialization is pretty exciting stuff. In my role, you see the customers’ needs and then you figure out what you can do to solve those needs,” Kher said. “Being a 100-year-old company that has always been on the cutting edge of innovation, it is very important for us to make sure the product is comparable with an existing product and yet brings us a really new technology that can solve an existing problem.”

Acteon GroupLaurent Zenou, Product Manager for SOPROLIFE

21 years with the company, worked on SOPROLIFE

Laurent Zenou remembers the first time he and his colleagues tried the prototype for the SOPROLIFE caries detection device in their own mouths. The look on their faces gave away their surprise as this optical unit kept finding cavities in their mouths, cavities they didn’t know they had.

Zenou describes this product as one of a kind, “something that’s opened the door to a new generation of products to aid in the detection and treatment of oral diseases.” As product manager, he was involved in the heart of this project from the time the company’s engineers discovered the property of auto-fluorescence on dental hard tissues. He followed the clinical studies, participated in product definition, chose materials, colors and features, and then introduced the SOPROLIFE to the sales forces, users, opinion leaders and dental universities all around the world.

From the beginning, it was clear to Zenou and everyone else working on this project “that linking fluorescence with intraoral camera would revolutionize the diagnostic methods.” To make that happen, it would take work from a lot of different people in the company and talented people from many different trades, including electronic engineers who specialize in signal processing, precision optics, mechanical engineers, designers and many researchers from the dental world such as professors and specific laboratories.

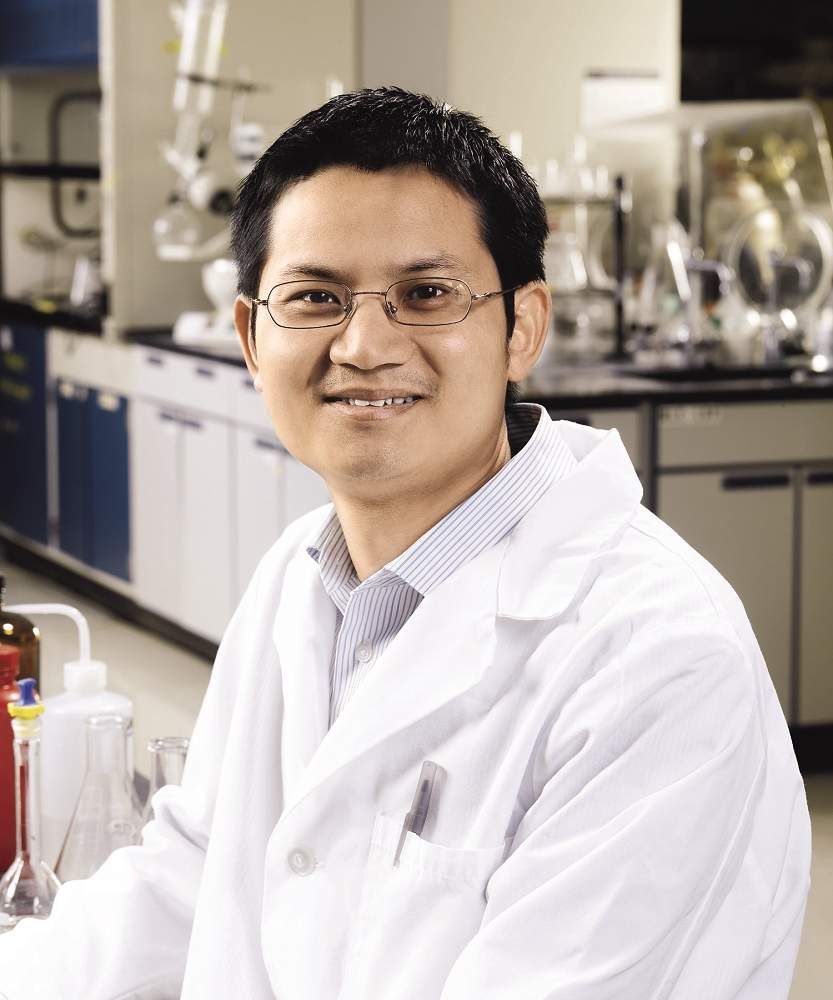

BiscoLiang Chen, PhD, Senior Research Scientist

3 years with the company, worked on Z-Prime Plus

What was your role in the development of Z-Prime Plus?

I have a special expertise in organic chemistry, organic synthesis and organo-metallic chemistry. Zirconia-based crowns and bridges are rapidly becoming the esthetic alternative of choice to traditional PFM. Dentists communicated to Dr. Byoung In Suh (the founder of Bisco) and Bisco of the need to confidently bond to zirconia. Dr. Suh empowered me to develop a material to resolve these issues, which ultimately led to Z-Prime Plus.

What is involved in developing a product like this?

Success requires the help of many others. Product development is the result of synergistic feedback between dental professionals and talented researchers.

It is a two-step interactive process between R&D and product management. It begins with diligent research to provide a scientific understanding of the current clinical results, challenges and possible solutions. The next step is the innovative, solutions-based development of interactive chemistry to address the challenges of current and future clinical direction. Once chemistry is developed, it must be able to pass the rigors of the Quality Manufacturing Process of Predictability and Reproducibility. It is now the creative feedback from teams of dental professionals that will ultimately finalize the formula. The product must then be exhaustively tested per numerous specifications (including FDA) mandated by quality systems.

What do you think dentists would be most surprised to learn about the behind the scenes of product development?

How similar the emotions are. Creating materials is very self-reflective, labor intensive, and I am always challenging my thought process and using a cognitive, pragmatic approach that is very similar to the dental clinician.

What is your favorite part of product development?

Accomplishment. When an independent agency replicates my results and Dr. Suh pulls me aside and says “good job.” I feel so much pride in accomplishment when I can be part of a solution by providing clinicians with a material that allows them to address a clinical challenge.

Lanmark GroupHoward Klein, President

12 years with the company

The manufacturer starts with an idea. Lanmark Group helps commercialize that idea and introduce it to the dental professionals who will use it in their day-to-day practices.

From market research to the integrated marketing plan, this advertising marketing communication group typically is involved with a product launch from day one. “We always recommend conducting preliminary research to determine if there’s a need for the product to be brought to market and to help ensure the proposed product’s features and benefits meet the market’s needs,” Lanmark President Howard Klein said.

After the marketing research phase, which includes focus groups, surveys, and one-on-one interviews, Lanmark transitions to help build an integrated marketing plan that includes education, advertising and promotion. And that education piece is key to a successful launch, Klein said. “No matter how great a product is, if the manufacturer doesn’t take the time to educate dental professionals about how it can change the way they practice dentistry for the better, it’s pretty safe to say the product won’t get very far from the launchpad. We see a lot of really great products brought to market that quickly fail or that are never fully embraced by the profession because of the lack of education and training, It’s really important for companies to consider this when launching products and budget appropriately.”

Lanmark has been orchestrating successful dental product launches for more than 30 years, and even introduced the first power toothbrush to the market. A multi-department team of 8 to 12 individuals works with each of the agency’s current 36 clients, work that begins from the beginning, conceptual phases and supports the product throughout its entire life cycle.

“The best-case scenario is getting involved with clients at the ground level, when they have a new product idea, and then working with them from the beta testing phase, to the actual launch stage, and then beyond to bring their product to market. We also do everything possible from an integrated marketing perspective to create and maintain industry awareness,” Klein said. “Advertising, interactive marketing, public relations, ongoing research, professional relations, events marketing, and social media are all considered before we develop a marketing mix that is appropriate for the client’s strategic and business objectives.”

Innovative HealthTechnologiesDr. Chris Robertson

Developed the aveoTSD, distributed in the U.S. by Glidewell Dental Laboratories

For Dr. Chris Robertson, it’s not just a job.

Dr. Robertson, an orthodontist, became passionate about sleep medicine not long after his father died from what he suspected was Obstructive Sleep Apnea. He learned about this disorder five years later at a conference in Christchurch, New Zealand. At that time, most people had never even heard of Obstructive Sleep Apnea, let alone knew how to treat it. From there, Dr. Robertson began his extensive research.

“Unfortunately over the ensuing years, it became apparent that these devices in many patients were causing occlusal or bite changes. This led me to undertake a 100-patient longitudinal prospective study over 3 years to demonstrate these changes with the use of cephalometrics,” Dr. Robertson said. “In all, this research took 8 years and resulted in a Doctorate in Dental Sleep Medicine from the University of Otago, New Zealand. The occlusal changes prompted research into a different mode of treatment for these patients. At that stage there was no treatment options available for the treatment of edentulous or semi-dentate patients with oral appliances.”

Over the years, Dr. Robertson designed several products to treat snoring, with the Aveo Tongue Stabilizing Device (aveoTSD) the culmination of that work. He spent years developing this product, which now is distributed in the U.S. by Glidewell Dental Laboratories as an anti-snoring device. It’s been a long and expensive process to get the product to the international marketplace, Dr. Robertson said, but it’s time and money well spent.

The aveoTSD uses gentle suction to prevent the tongue from falling against the back of the throat, keeping the airway open during sleep. A result of the all-important user feedback, the device is now configured into three sizes: small, medium and large along with two Uni-Spacer’s of 4 and 7mm for extra titration. There is also a Professional Sizing Kit available for the dentist with all three sizes and Uni-Spacers to fit the patient with the correct size.

Dr. Robertson has seen how the aveoTSD has helped patients reach long-lasting compliance and how it has helped them sleep better. The benefits are vast, and for Dr. Robertson that’s the best part of product development.

Hu-Friedy Mfg. Co. Inc.Ann O’Connor, RDH, General Manager Preventive Strategic Business Unit

5 years with the company (newly rejoined in 2010), worked on the Total Solution Implant Maintenance Kit

How did you determine the Total Solution Implant Maintenance Kit was needed in the market?

We strive to be in tune with the key opinion leaders. In this case, there was a lot of courses and questions coming up about implants, and the care of implants as the market continues to grow. So, we conducted research with more than 500 clinicians, and found that they had a lot of questions about what are the best practices for approaching implant maintenance care.

What are some of the steps involved with product development?

It certainly starts with discovery and culminates with the product launch. Behind the product launch, there is extensive research to uncover what the clinician wants, needs and desires in their dental product. Then we look at technical merits and its marketability and then we transition to the feasibility phase. That leads us to the development phase, which includes the design plan, the manufacturing plan and the marketing plan. At Hu-Friedy, we put a lot of emphasis on testing throughout the developmental process prior to the actual launch.

Why is testing such an important piece?

At Hu-Friedy, we consider ourselves to be an extension of the clinician’s hands. Quality and safety for both the clinician and the patient are of paramount concern to our company above anything else.

What is your favorite part of the product development process?

I favor the discovery process. I really enjoy envisioning what is the next best idea or product that we can bring to market. That starts our journey toward exciting solutions that we can bring to the clinicians we serve. I am always looking for what that next idea, project or instrument is going to be.

What would you like readers to take way from this?

The process of innovating dental instruments for us never ends. Hu-Friedy is all about continuous improvement and providing products with clinicians in mind that are going to help them achieve the best clinical outcomes.