Unprecedented “Like New” Performance for the Entire Life of the Insert – Introducing Parkell’s New DuraTip® Inserts

[SPONSORED] By raising the bar on the standard of care over the entire life of the insert, Parkell’s DuraTip ultrasonic inserts are reinventing the way clinicians view insert wear.

Image Credit: © Parkell

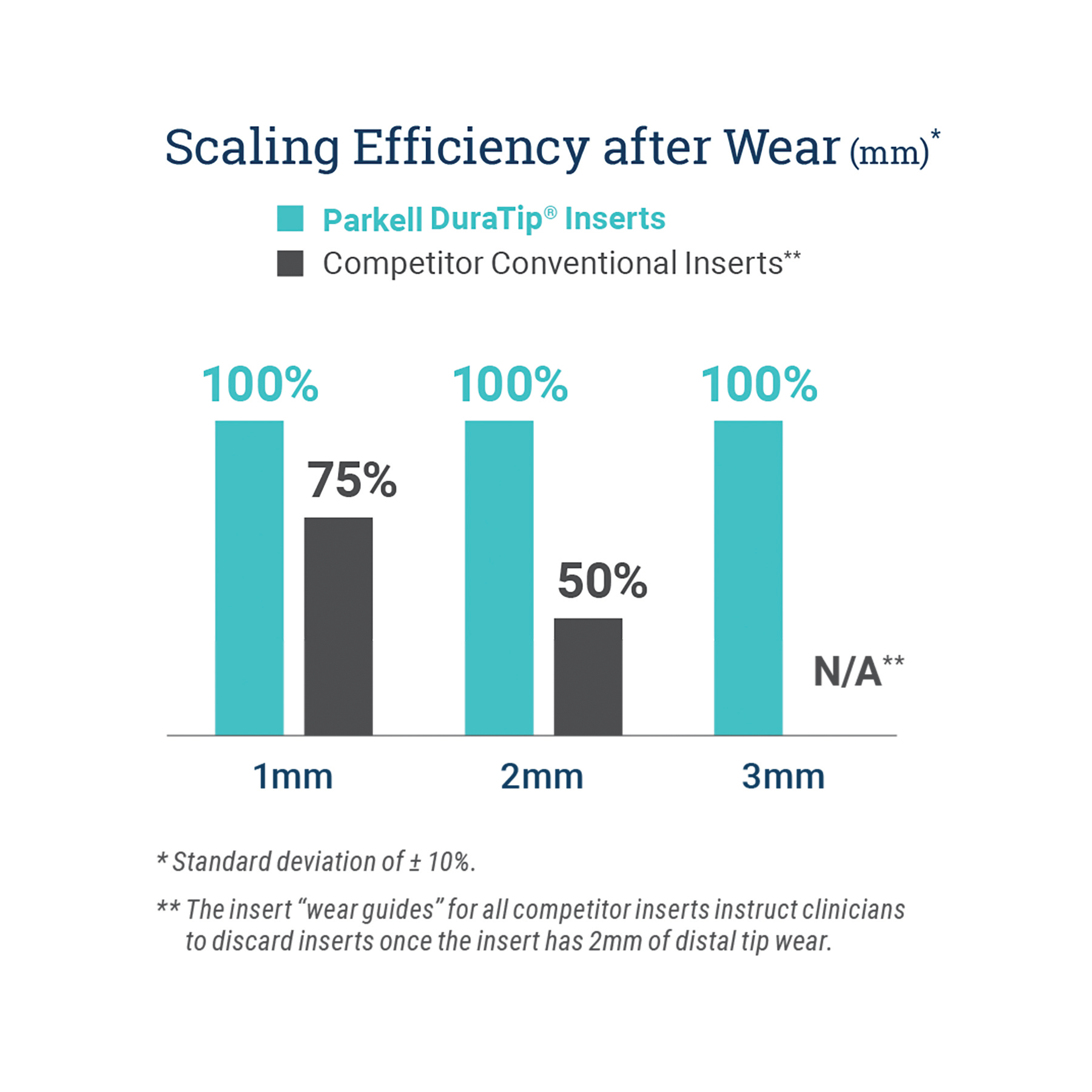

In collaboration with a team of hygienists, Parkell’s insert engineers devoted thousands of hours to create DuraTip® ultrasonic inserts and achieve what was previously considered unthinkable; continuous excellence across an entire 3 mm of wear. DuraTip inserts shatter the industry standard of progressive efficiency loss over 2 mm of tip wear, by providing optimal performance for not just 1 mm, not just 2 mm, but for an entire 3 mm of tip wear.

Widely known, but rarely considered, insert tip wear can greatly affect the efficiency and performance of an ultrasonic insert. Traditionally, when the insert tip loses 1 mm of length from wear, it results in approximately a 25% loss of scaling efficiency. When wear reaches 2 mm, efficiency is reduced by an astounding 50%.

Unfortunately, instead of replacing the insert when warranted by excessive wear, clinicians may try applying additional pressure to compensate for this loss in efficiency, incorrectly thinking this additional force will make up for the loss of effectiveness. In actuality, the exact opposite is true, the additional force lessens the vibration of the tip, thereby making the insert even less effective.

The consequences of tip wear can be severe, causing harm and discomfort to both patients and clinicians alike. For the patient, a worn insert may not only be unable to remove calculus from the root surface but may also cause more pain during the procedure. For the clinician, in their efforts to remove stubborn deposits, applying increased pressure to the insert, dampens the amplitude, lowers the energy transfer, and reduces tip movement, the result of which is diminished cleaning efficiency and effectiveness. Do you really want to put your hand and wrist at risk by scaling all day with inserts that are worn beyond usability? The time is now to just say NO to contributing factors to hand strain, wrist fatigue, and carpel tunnel syndrome.

This patented technology and unmatched ability to maintain peak performance for an entire 3 mm of tip wear, makes DuraTip inserts ideally suited for every stage of patient care, while also offering the dental professional the advantage of being able to stay on schedule, maintain their hard-earned stellar reputation, and most importantly, provide exceptional treatment.

By raising the bar on the standard of care over the entire life of the insert, Parkell’s DuraTip ultrasonic inserts are reinventing the way clinicians view insert wear. From cradle to grave, DuraTip inserts provide the ability to maintain an unprecedented level of performance over their lifecycle, which is a tremendous value for every office’s hygiene department.

Parkell is confident that it’s just a matter of time before DuraTip inserts are recognized for their incredible value, longevity, durability, and consistently excellent performance patient after patient.

DuraTip’s excellence is achieved through novel patented internal geometries at the tip and connecting body, and unsurpassed energy transfer and durability across an innovative W-stack design for optimized performance and effective deposit removal. The W-stack design also decreases the risk of damage during handling and instrument processing. While traditional stacks are prone to bending that leads to a decrease in energy and the ability to make the tip move efficiently and effectively, DuraTip’s stack design provides greater rigidity and stability over time.

DuraTip inserts are designed and manufactured in the USA. Parkell’s quality-control process assures spot-on frequency, 100% stroke testing and ideal water flow. DuraTip is currently available in 30K Universal Slim and 30K Perio Slim.

It is time to raise the bar with Parkell’s new DuraTip insert – experience the same “like new” performance for the entire life of the insert.