How to obtain state-of-the-art esthetics, precision and biologic stability with dental implant restorations

This technique features Straumann products combined with the latest CAD/CAM technology to create a polished, esthetic result.

Today’s ideal implant restorations demand the highest level of machining tolerance and the ability to withstand extreme functional and parafunctional forces while attaining outstanding esthetic match to natural teeth.

While CAD/CAM technology has radically changed how we achieve these parameters, there often is a tradeoff between strength (titanium) and esthetics (zirconia) in the selection of abutment material. The introduction of Straumann®’s Variobase® abutment provides the solution to meet all these parameters with a simple workflow, allowing every dental laboratory access with minimal to no capital investment.

Use of an implant manufacturers’ proprietary titanium base provides the reliability and precise fit of an “original-on-original” interface between implant and abutment. The added security of a tapered titanium abutment into an internally tapered titanium implant, torqued into position by a tapered head titanium screw, matches all surface characteristics to reduce wear. This will maintain precise fit tolerance and minimize potential micromovement associated with negative biologic consequences.

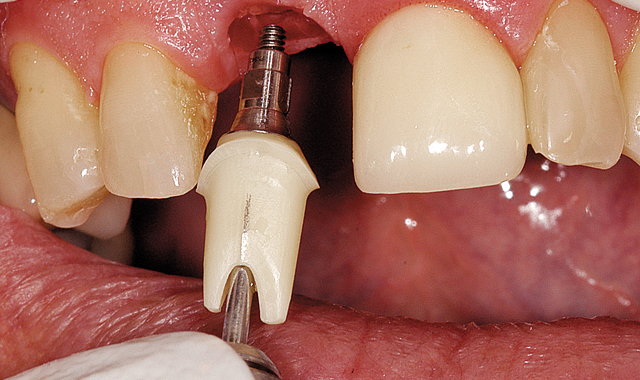

The mating of a CAD/CAM- designed and manufactured zirconia coping (Straumann® zerion®) bonded to the titanium base allows for precise placement of cement line and angulation correction for cemented restorations with ideal support.

Related reading: Straumann introduces comprehensive solution for treating edentulous patients

Of equal or greater significance is the ability to provide a full-contour or veneered screw-retained restoration, eliminating any chance of subgingival cement and associated negative consequences. The popularity of screw-retained implant restorations has shown a significant increase in the past few years, allowing easy retrievability and minimizing peri-implant disease secondary to inadequate cement removal. The limitation to providing a screw-retained restoration is screw access through the facial aspect of an anterior restoration.

This combination of titanium abutment and CAD/CAM-produced zirconia coping now allows for ideal esthetics with no compromise in strength for both restoration types.

An ideal workflow allows any dental laboratory to provide these results to their doctors with no significant investment or change to daily routine. The technician can send a stone model to Straumann®’s Scan & Shape service for design and fabrication (or laboratories with CARES®, Dental Wings or 3Shape scanners can send a design file to Straumann’s Arlington, Texas, milling facility). The technician is given the opportunity to view and approve the design prior to fabrication, if desired. The Variobase abutment and milled component are returned to the laboratory. The technician would then simply bond the components together and complete the final restoration.

The Straumann Variobase also provides an outstanding solution to screw-retained posterior restorations with full-contoured zirconia, lithium disilicate or custom porcelain veneering.

Step-by-step: A complete solution from chairside to benchtop

Continue to page two for the case studies...

Patient 1

The first patient illustrated presented with the need to replace his maxillary right central incisor due to vertical root fracture. A Straumann® Roxolid® RC Bone Level Implant was placed with immediate provisionalization (RC temporary abutment Vita CAD), left out of any occlusal contact and allowed to integrate for eight weeks. This patient’s bruxism habit and associated wear of the lower incisors made the choice of a full CAD/CAM titanium abutment appealing due to ideal strength.

Patient esthetics expectations and the desire to place a lithium disilicate (IPS e.max® by Ivoclar Vivadent) crown made a full CAD/CAM zirconia abutment appealing, allowing for elimination of underlying metal and the ability to maintain translucency in the final restoration. The selection of a Straumann Variobase Abutment provided the ideal mix of strength (titanium base) and esthetics (zirconia) with matched machining tolerance and surface characteristics between crown, abutment and implant. While a full-contour screw-retained restoration would eliminate any potential of cement below the peri-implant tissues and allow for simple retrievability, the screw access position precluded this appealing option.

Technique: How to cooperatively fix a failed cosmetic case

The design and fabrication of the CAD/CAM zirconia component was accomplished by Straumann CARES Scan & Shape with ideal cement line position and support for the restoration.

A “stump” shade was provided to the laboratory for selection of the zirconia shade, as well as a final shade for fabrication of the definitive lithium disilicate crown (IPS e.max® by Ivoclar Vivadent).

The laboratory bonded the milled zirconia coping to the Variobase abutment (Panavia™, Kuraray Dental), inspected and removed residual adhesive under magnification and returned the abutment and crown for delivery to the patient. The Variobase abutment (Ti base with adhesively attached zirconia component) was delivered to 35 Ncm, the screw access sealed and IPS e.max® crown (Ivoclar Vivadent) cemented.

Continue to page three for more...

Patient 2

The second patient (a 24-year-old male) lost his maxillary central incisor due to extensive resorption secondary to trauma sustained five years prior. Five months after removal of the tooth and a grafting procedure, a Straumann Roxolid Bone Level implant was placed with immediate provisionalization.

Eight weeks later, an impression was made, and the laboratory selected the Straumann Variobase abutment due to the high esthetic site with a thin scalloped gingival architecture and high smile line).

Based on ideal anterior placement with the screw access being slightly palatal, the Variobase abutment was veneered with porcelain for a screw-retained restoration.

Technique: Pouring better models with Wonderfill

Patient 3

The third patient had a mandibular molar replaced with a Straumann Wide Neck Tissue Level implant. Due to the soft tissue height, restorative options were limited to a CAD/CAM abutment (to place to finish the line at an ideal position relative to the tissue) with a cemented restoration or a screw-retained restoration to eliminate any cement concerns. Due to the limited interocclusal restorative space, a screw-retained restoration was most ideal. Straumann’s Variobase abutment was selected and a full-contour zirconia crown fabricated.

Once the abutment and final full-contour restoration were fabricated by Straumann, the laboratory bonded these together. The final restoration was placed to 35 Ncm and screw-access sealed.

Thank you to Marcos Aleman, MDT (Aleman Laboratory, West Palm Beach, Fla.), for the planning and final restorations.

View a video of the technique below:

More from Straumann: Straumann introduces Variobase abutment for CEREC