The conservative alternative

February 2010 | Dental Products ReportClinical 360° : You and your lab The conservative alternative How to best maximize results and minimize trauma when fixing a chipped zirconia bridg

February 2010 | Dental Products Report

Clinical 360° : You and your lab

The conservative alternative

How to best maximize results and minimize trauma when fixing a chipped zirconia bridge.

By Matt Roberts, AAACD, and Dr. Franklin Shull

First-Hand Advice The “You and Your Lab” feature allows successful dentist/dental technician teams to share some of their secrets to working well together and providing lasting, beautiful results for patients.

Dentists and laboratory ceramists alike have experienced it. Each finishes their respective part of a case that they’re especially proud of. They pat themselves on the back, and the patient is sent home. Then, at a later date, the call comes in: “My front tooth chipped.” The prospect of repairing or replacing the ceramic restoration is disheartening.

Fig. 1 Fig. 2 Fig. 3

FIGS. 1–3 Patient returns with fractured incisal of No. 9, the mesial abutment of the zirconia bridge (Fig. 1). No. 9 is prepared for an individual veneer-care is taken not to uncover the zirconia core material (Fig. 2). Final result of the e.max veneer bonded to the prepared surface of No. 9 (Fig. 3).

As in the example here, closer examination reveals the chip is located on an abutment of a zirconia bridge. Replacing the bridge would require cutting off three or more units and redoing them. An alternative dentists and their ceramists can pursue requires the dentist to cut a thin preparation in the facial of the layering ceramic, carefully avoiding the zirconia itself. The ceramist then can wax and press a thin lithium disilicate (IPS e.max Press) veneer to recreate the initial shape and form of the tooth, and prepare the veneer by etching it in the laboratory. The dentist bonds this restoration over the zirconia bridge. This requires isolation with rubber dam and rubber dam sealers, after which the surface of the preparation is etched with hydrofluoric acid. Silane is applied to the veneer and preparation, and a very thin layer of resin cement is used to bond the lithium disilicate restoration over the zirconia bridge and complete the repair. The result is a stronger incisal third that is less likely to fracture and avoids the trauma of removing the multi-unit bridge.

Before implementing this technique, evaluate the extent of the fracture. If there is significant zirconia exposed, removing the bridge may be the best option. In this example, the fracture was entirely in the layering porcelain. Similarly, when dealing with PFM restorations, the hope is to avoid the metal substructure. If a small area of metal is exposed, opaquing agent would be needed to mask the darkness. Avoid trying to just add back the porcelain piece. Select your repair material, and remember lithium disilicate is optimal for this type of repair because it can be pressed very thin, yet still demonstrate very good strength.

WHAT THEY USE...

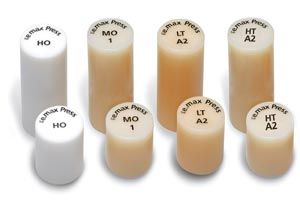

IPS e.max press

This lithium disilicate glass-ceramic (LS2) offers excellent fit, form and function combined with high strength of 400 MPa. The material is supplied in four levels of translucency and two sizes for maximum flexibility. The resulting restorations exhibit lifelike esthetics, independent of the shade of the preparations.

800-533-6825

ivoclarvivadent.com

Join the Discussion

- Comment on this and other articles on our Facebook page