Amann Girrbach, TRI Dental Implants Partner for New Digital matrix Implant

The new matrix® implant is designed for new digital manufacturing technologies.

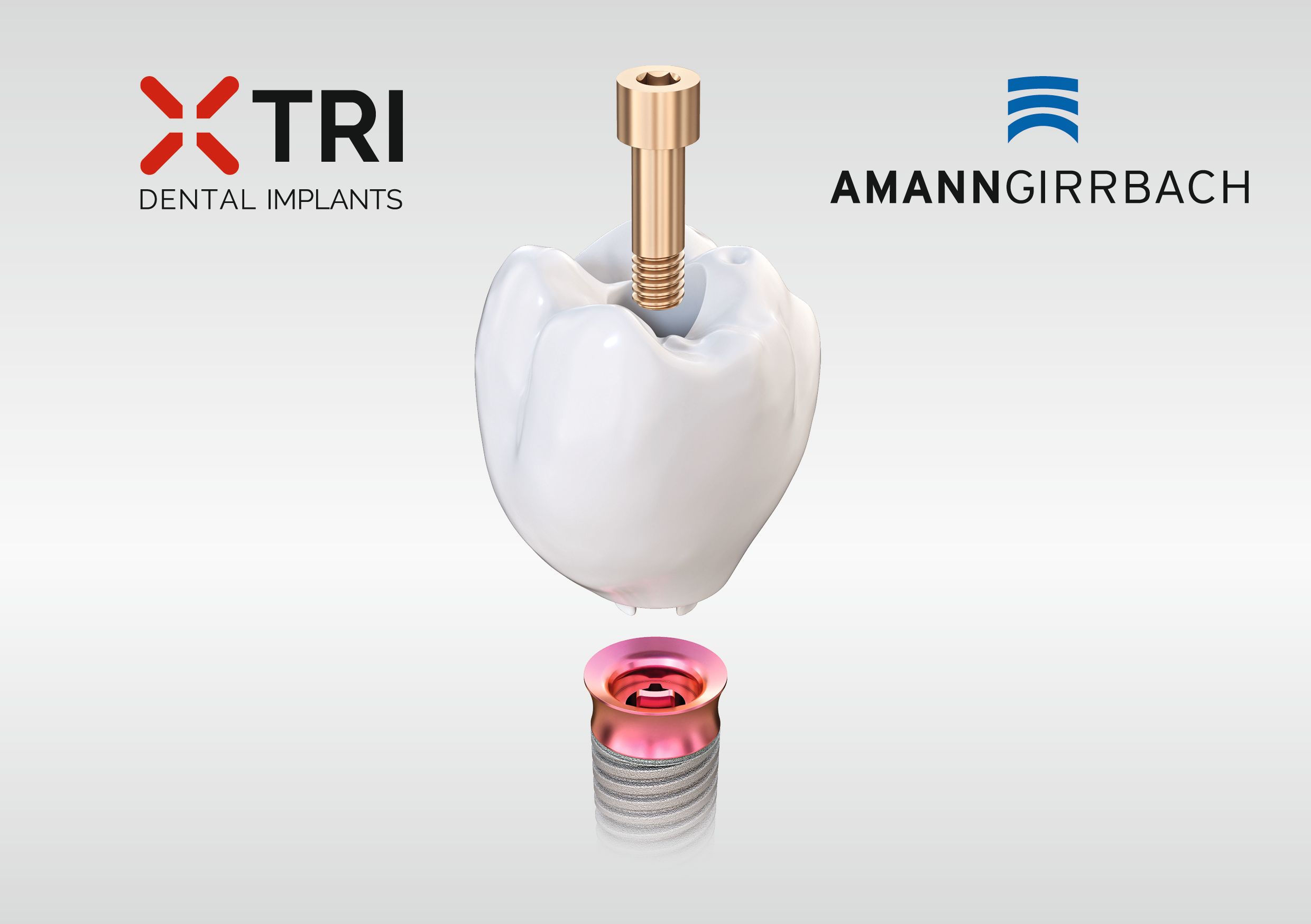

Amann Girrbach and TRI® Dental Implants have partnered to release a new dental implant product that is said to not require the use of an abutment.

The new matrix® implant is designed for new digital manufacturing technologies such as CAD/CAM milling or 3D printing. This concept allows for the planning of dentures directly on the implant—for single crowns, multi-part bars and bridges, or full arches— without any need for an abutment. The matrix implant is also designed to offer no restriction on angulation and indication, no need for cementation, as well as the option to digitally plan 100% patient-specific emergence profiles, which are all said to guarantee long durability and highly esthetic results.

TRI Dental Implants has found the perfect partner for the realization of the restorations in Amann Girrbach. Amann Girrbach is a system provider of CAD/CAM solutions for the laboratory and dental practice and provides its users with validated workflows offering maximum efficiency and safety. This also applied to the project with TRI Dental Implants: in addition to detailed process validation of software and machine, a number of different materials were also validated. For example, in the future, it will be possible to fabricate high-precision crowns from Zolid DRS or Zolid Gen-X directly on the implant without compromising either function or esthetics, according to a press release from Amann Girrbach. In combination with the Ceramill Therm DRS sintering furnace, the final result is available in just 20 minutes.

“In a rapidly changing market for dental implants, there is often talk of a 'fully digital workflow', but in reality, numerous manual steps such as bonding and cementing are still required,” Sandro Venanzoni, chief technology officer at TRI Dental Implants said in the press release. “With the matrix concept, we now have a 100% CAD/CAM-compatible implant system and a digital workflow. The cooperation with Amann Girrbach was crucial and also extremely valuable for the development of matrix."