3D printing the future of dentistry

Digital Esthetics and Dental Products Report round up the latest innovations in 3D printing.

There may be no technology more hyped than 3D printing. It seems like every week there’s a news report about some new and amazing creation that was made with 3D printing or metal sintering technology.

And to be sure, these results are incredible! But we wondered how that technology is changing dentistry. What’s out there for the dental professional looking to see how 3D printing is making an impact in the operatory, the laboratory and beyond?

This is the question the following product roundup attempts to answer. These are some of the industry’s leading options for 3D printing and sintering (a sort of “printing” in its own right). If you’re looking for new technology to incorporate in your workflow-to create surgical guides, temporaries, models, try-ins or other options-one of these remarkable machines ought to fit the bill.

Must read: Predicting the future of 3D printing

As always, we’re curious about the ways technology is changing dentistry. And if the futurists are right, this is just the beginning for 3D printing. We’re excited to see what’s just around the corner.

Click the next button to see innovations in 3D printers ...

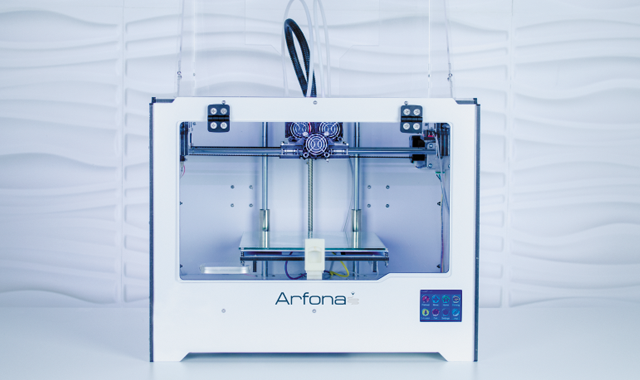

r.Pod® Desktop 3D printer

Arfona and Valplast have entered into a joint distribution agreement that brings extrusion-based 3D printing to the dental industry with the r.Pod Desktop 3D Printer. Capable of printing thermoplastic filament, r.Pod prints flexible partial dentures, study models, custom impression trays and soft tissue gingiva for implant models. The new r.Pod printer is also optimized for printing Valplast® flexible nylon resin for partial dentures and appliances. Though typically not used in dentistry because of limitations on resolution, extrusion-based printing can offer a number of advantages over more common resin type printers. By printing thermoplastic resins the r.Pod can create end-use parts and dental appliances as opposed to prototypes or diagnostic appliances that are typically printed on DLP and SLA printers. r.Pod is a dual extrusion 3D printer, containing two nozzles that can be used to print parts with removable support material or multicolor/multimaterial parts. The process for designing 3D printable Valplast partials has been validated using the 3Shape RPD module, while other CAD systems are currently being tested.

Arfona

718- 290-9300 | arfona.com

Perfactory Vida

Launched by EnvisionTEC in May 2015, the Perfactory Vida is engineered to be a workhorse 3D printer in the digital dentistry workflow, offering high productivity and flexibility of material choice. The low-cost, user-friendly 3D printer boasts a build envelope of 5.5” x 3.1” x 3.95”, enough room to print 10-12 full models per job, based on model size. A high-resolution projector offers 1920 x 1080 pixel resolution with custom UV optics. The final printed parts demonstrate accuracy down to 73 µm, with reportedly excellent surface quality. The Vida’s key differentiator is the range of proprietary dental materials in which it prints, which allow for a full range of functionality, such as models to create clear aligners with thermoforming, bite splints and guards, surgical drill guides, wax-like partials for direct investment casting and more. The Perfactory Vida is also compatible with multiple software design packages, such as 3Shape, Orchestrate 3D, Dental Wings and exocad.

EnvisionTEC

313-436-4300 | envisiontec.com

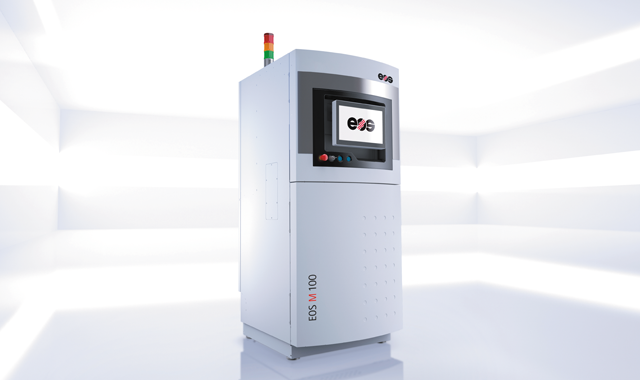

EOS M 100

The size and modular design of the EOS M 100 make it ideal as an entry level model for additive manufacturing. In terms of process and component quality, it corresponds to the EOS M 290, one of the leading systems on the market for Direct Metal Laser Sintering (DMLS). The beam quality of the EOS M 100 and stable performance of the 200 watt fibre laser reportedly guarantee optimum, constant processing conditions for the production of high-quality components. The smaller laser spot with excellent detail resolution is said to be ideal for manufacturing highly complex, sophisticated DMLS components. The building volume and efficient recoating and exposure strategy reduce secondary time, so that parts can be produced quickly and efficiently in small quantities. Thanks to the modular inner design and the powder supply bin, setup and shutdown only take minutes, changing material is straightforward and maintenance is done quickly. Finally, peripheral devices are matched to the industrial manufacturing process and ensure minimum powder contact.

EOS

248-306-0143 | eos.info/dental

Form 2

Formlabs’ Form 2 desktop stereolithography 3D printer is designed to be the most advanced desktop 3D printer on the market. The Form 2 reportedly enables large prints, incredible resolution, connected capabilities and an intuitive printing experience for professionals. In recent years, dental applications in desktop 3D printing have rapidly taken off. Formlabs’ products are said to have become indispensable tools for dental innovation. Dental professionals can use the Form 2 and Formlabs’ Dental SG resin to create surgical guides, educational models, bleaching trays, retainers, aligners and more.

Formlabs

617-702-8476 | formlabs.com

Objet Eden260VS Dental Advantage

Stratasys’ goal is to be at the forefront of innovation by empowering companies to untangle complexity, tackle tough challenges and uncover new solutions with 3D printing. Within the Stratasys Dental Series, the Objet Eden260VS Dental Advantage is designed to give growing labs the ability to streamline production of dental models, orthodontic appliances and surgical guides. The easy-to-use, office-friendly 3D printer reportedly builds models directly from digital files two times faster than other low-cost dental 3D printers. It is engineered to deliver the lowest cost per part with the accuracy and consistency needed for fine details and complex surface geometries. With four specialized materials, the Eden260VS is said to have the versatility to handle a variety of dental and orthodontic applications. It is more efficient for growing labs needing to streamline production at a low cost.

Stratasys

800-801-6491 | stratasys.com

BEGO VARSEO 3D printer

The VARSEO 3D printer, developed by BEGO, is engineered to help dental labs achieve fast, simple and cost-efficient fabrication of a wide range of dental indications. The printer is able to produce surgical guides, models, CAD/Cast partial dentures, splints and individual impression trays. The printer, an open STL file device, uses a range of low-consumption materials and features a user-friendly display for fast and easy access to all of the printers’ functions. The printer also features an ejector system designed to minimize distortion and a cartridge system that allows users to change materials (that have a long shelf life) within a few seconds. There is also reportedly no aging of the resin through closed cartridges.

Zahn Dental

800-496-9500 | zahndental.com