10 Things We Saw at IDS 2017 That Blew Us Away!

DPR looks at 10 amazing dental solutions, materials, equipment and systems that were on display at IDS 2017 in Cologne, Germany.

The recent focus in dentistry has been on digitizing and streamlining the design and manufacturing process, and evidence of that was everywhere at IDS. Processes in milling and printing are getting better, materials are getting stronger and more esthetic, communication between the dentist and lab is getting easier, and investments in new technology are getting much more affordable.

There are so many new products, materials, and technologies to consider in a piece like this, and it’s hard to even know where to start. There were 2,305 companies on display at IDS this year, and while there was no way to see all of them, we did our best.

Here are 10 things we saw at IDS that blew us away. Click the next button for a glimpse into one of the most impressive-if not the most impressive-dental trade shows.

1. The PrograMill line from Ivoclar Vivadent

Ivoclar Vivadent announced four new mills at IDS 2017: three designed for laboratory use (the PM3, PM5 and PM7) and one for chairside milling (the PrograMill One). The PrograMill One is the world’s smallest five-axis milling machine. In this new machine, the workpiece rotates around the tool, ensuring that the tool never leaves the block, reportedly leading to shorter milling times. It can mill a molar in 12 minutes (and within 17 minutes for the finest detail).

Used in combination with scanning and design solutions from 3Shape and paired with the IPS e.max material, these milling units are helping to usher in the era of digital dentistry, particularly with digital dentures.

To learn more, here's Dr. Sascha Cramer von Clausbruch, Director Product Management CAD/CAM Equipment at Ivoclar Vivadent, talking about the new PrograMill One:

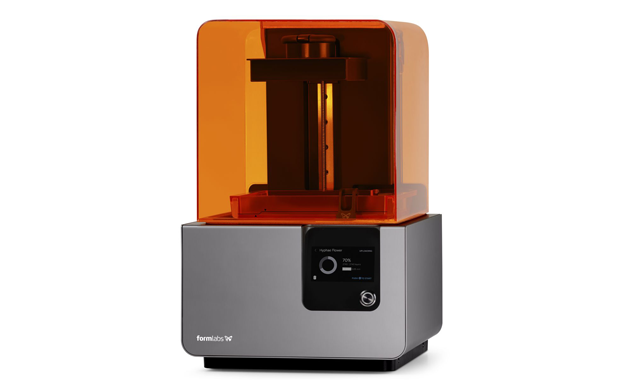

2. Form 2 Printer from Formlabs

Those interested in 3D printing (although, who isn’t?) flooded the Formlabs booth at IDS to see the daily live presentations of the Form 2 printer.

The earlier version of the printer-the Form 1-is the world’s most best-selling printer, and at a price point of under €4,000, it’s no wonder it is still attracting so much attention. It has an incredibly small footprint, so it’s easy to see it in a dental office or in a large-scale dental lab (many of which have several Form 2 printers, thanks to the low cost).

If you want to see where 3D printing is headed, look at the Form 2. It has the capability to print large builds at higher details, and it’s said to be the most advanced desktop 3D printer ever created.

3. VPI Emergence Profile Management System from Innovato Holdings

A new company stood out within endodontics. Innovato Holdings is the creation of Dr. Ioannis Vergoullis, DDS, and his lab technician partner George Papadopoulos, CDT, who wanted to offer improvements and consistency to implants by creating an emergence profile management system, VPI EPMS.

Related reading: More impressions about this innovative solution from IDS 2017

The VPI EPMS includes a mold template that assistants can use to simply fabricate a custom healing abutment that replicates the natural shape of the emergence profile, regardless of size. The VPI EP Indicator helps clinicians determine the proper size and shape of the healing abutment that the patient needs. It can also be used to mark or initiate the implant osteotomy. The kit also includes guide pins to evaluate the correct position and angulation of the implant.

“We want to pass the message to the dentist that the end result is very important and every patient deserves the best,” Dr. Vergoullis notes. “Either [dentists] pick this system or they use another methodology, but what’s important is to get the best result. We just offer a system that makes the process easier and faster.”

Innovato Holdings is already changing the endo game in Europe, and their products will be available in the U.S. later this year.

4. The X1 CBCT scanner from 3Shape

The X1 is a four-in-one scanner that combines CBCT, panoramic, ceph and face scans in one system while promising a lower dose of radiation. We couldn’t see the X-ray in action on the show floor, of course, but we were captivated by the life-like 3D face scans of attendees. It took just about a minute to do a full face scan on the X1, and though attendees were visiting and laughing while undergoing the scan, the X1 instantly created a detailed, realistic and clear image.

More: All the solutions shown off by 3Shape at IDS 2017

Scans are paired with the 3Shape Communicate cloud platform for sharing and treatment planning on software such as Implant Studio and Ortho Analyzer, and it’s clear to see how this four-in-one scanner creates a more comprehensive overview of patient morphology, leading to improved diagnostics and case acceptance. Check out our video of the 3Shape X1 in action on the show floor.

5. TruPrint 1000 from TRUMPF

Attendees were also drawn to the TRUMPF booth thanks to its new laser metal fusion printer. Videos in the background showed a comparison between a one-laser printer and TRUMPF’s multi-laser printer, which obviously beat its opponent in a race to the finish (without sacrificing quality, of course). Copies of the two models were on display at the booth, further demonstrating an emphasis on quality in the quest to increase production.

The TruPrint 1000 is a 3D printer that provides a multi-laser option for selective laser melting. By printing with two lasers, the TruPrint 1000 increases productivity by 80 percent, making it a potential hit with large laboratories. We spoked to Daniel Lichtenstein, Head of Sales and Market Development Additive Manufacturing at TRUMPF, who showcases the TruPrint 1000.

6. The Trefoil concept from Nobel Biocare

Another bustling block of show floor was operated by Nobel Biocare, which had crowds at every one of their innovation stations. One such station highlighted the new Trefoil concept, which fits a prefabricated framework over three implants to create a fixed, final, full-arch restoration. It can be placed on the day of surgery, and is adjustable, allowing clinicians to compensate for any inaccuracy in the placement of the implants.

Read all about the IDS 2017 announcements from Nobel Biocare

“The advantage of this system is that we do not have any temporary solution,” said Martin Gerlach, Senior Global Product Manager Implants at Nobel Biocare. “We want to offer more patients and a fixed and screw-retained solution instead of a removable one.”

The Trefoil concept will be available in the U.S. in 2018. Check out our video of Gerlach demonstrating the mechanics behind the new Trefoil concept for the edentulous mandible.

7. Digital Denture from Ivoclar Vivadent

I have to call out Ivoclar Vivadent for yet another impressive innovation on display at IDS: the Digital Denture process.

Read more: All about the Digital Denture process

Combined with the new PrograMill line as mentioned above, Ivoclar Vivadent offers a beautiful, monolithic denture in less time. The teeth are milled from the SR Vivodent CAD, a DCL disc that offers a more natural, esthetic tooth appearance, while the denture base is milled from the IvoBase CAD, a PMMA disc that provides durability and homogeneity.

“It’s extremely clever what we’re doing with the digital denture,” notes Mr. Robert Ganley, CEO of Ivoclar Vivadent AG.

8. Zolid HT+ from Amann Girrbach

Amann Girrbach had its new generation of materials on display at IDS called Zolid HT+, which, as all restorative materials aim to do, combines strength with esthetics. While the strength hasn’t improved by much (it’s still at the high-strength zirconia standard of 1,100 MPa), the esthetics are more natural than ever before.

Used with the Ceramill Stain & Glaze, restorations from these blocks will soon be available in 16 VITA tooth shades. In combination with the rest of the Ceramill system, Zolid HT+ helps make a fully digital, highly esthetic denture process possible.

9. TRIOS 3 Wireless from 3Shape

People poured into the 3Shape booth throughout the trade show and the interest in the new TRIOS 3 Wireless intraoral scanner was evident.

Live from IDS 2017: Learn about all the 3Shape developments shown off

Before the 2017 International Dental Show in Cologne, 3Shape teased “major developments” to TRIOS, and they weren’t lying. Now that TRIOS 3 is wireless, clinicians have even more flexibility in the operatory to move freely now that intraoral scanning with TRIOS is no longer tied to a computer (instead, it connects to the software through Wi-Fi). TRIOS 3 Wireless is powered by long-lasting rechargeable batteries that can be easily switched out to enable non-stop scanning. As with the original, TRIOS 3 Wireless also acts as a remote control to provide a seamless transition from patient to screen with one tool. Full-mouth scans, including occlusion, can be done in under a minute to help increase practice productivity and help provide same-day dentistry. The new wireless scanner promises to change impression taking forever. Check out this video of a live demonstration on the show floor at IDS 2017.

10. A 3D-printed REPLICATE Tooth by Natural Dental Implants AG

Rounding up our selection of the coolest products on the show floor at IDS is the recent development of a 3D-printable REPLICATE Tooth, which is currently available in Europe and will be available in the U.S. pending FDA approval.

The 3D-printed REPLICATE Tooth is made up of a titanium root portion fused to a zirconia abutment portion, similar to the currently available milled version. This one caught our eye for two reasons: First, the more natural approach to implants seems much less invasive, and the option to print the implant gives patients an immediate option. The current milling process relies on the dentist to submit the data for the implant prior to extraction so the REPLICATE Tooth can be manufactured to fit into the patient’s current tooth socket, eliminating the need to drill. Having the option to print the implant could result in a faster treatment and a faster healing process.